Back to the offer |

1

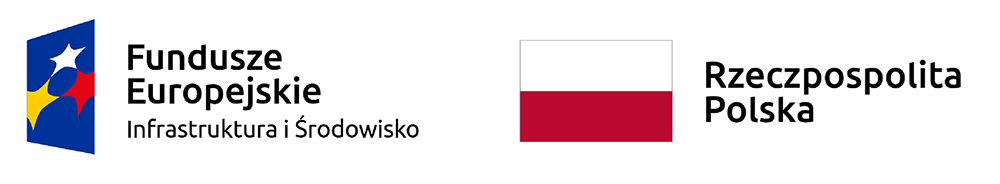

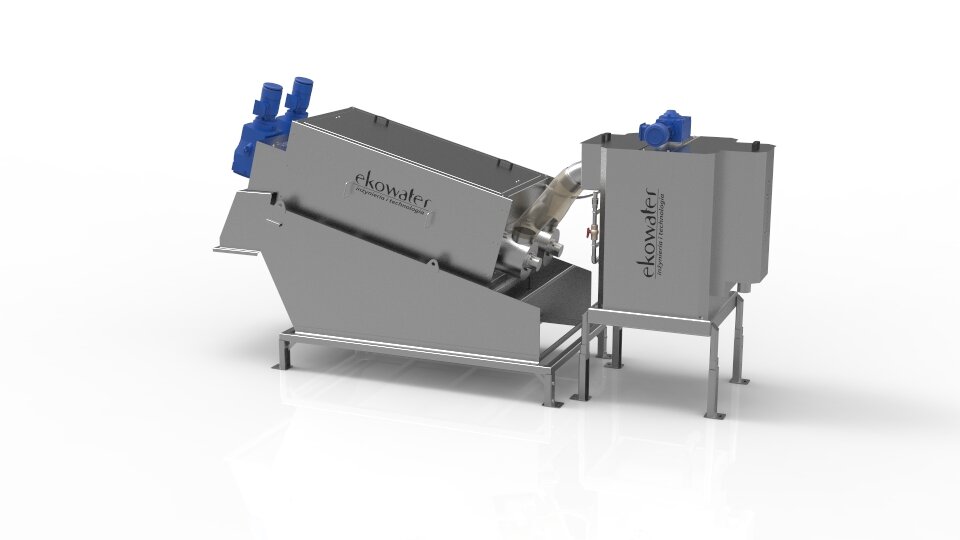

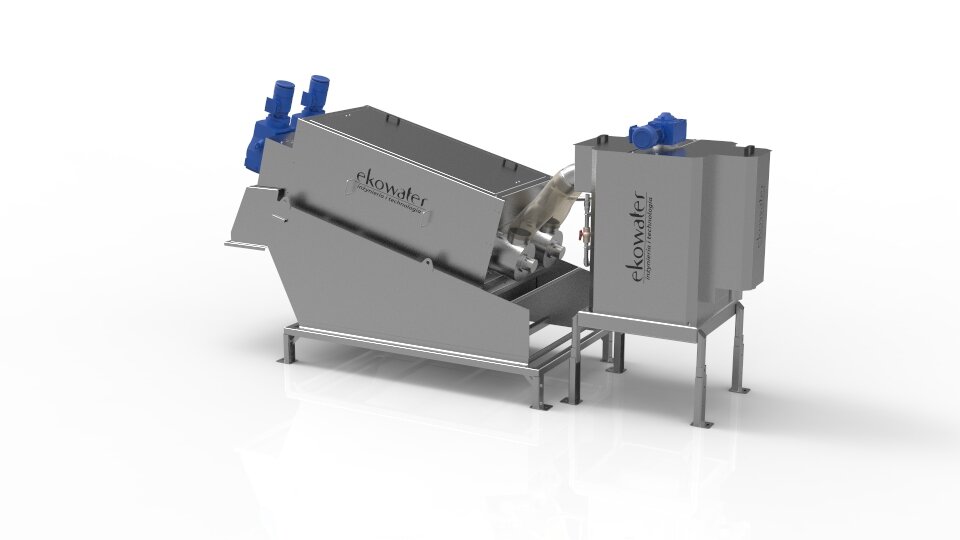

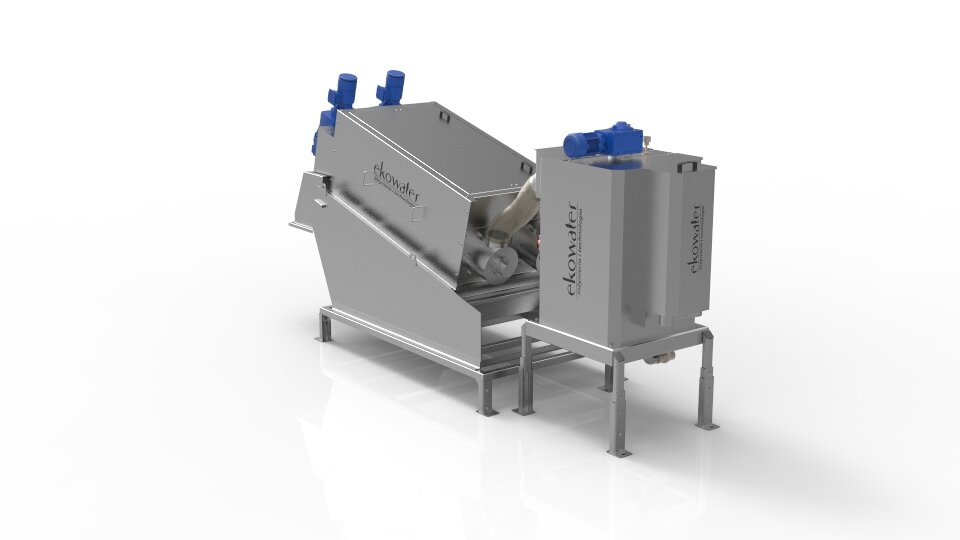

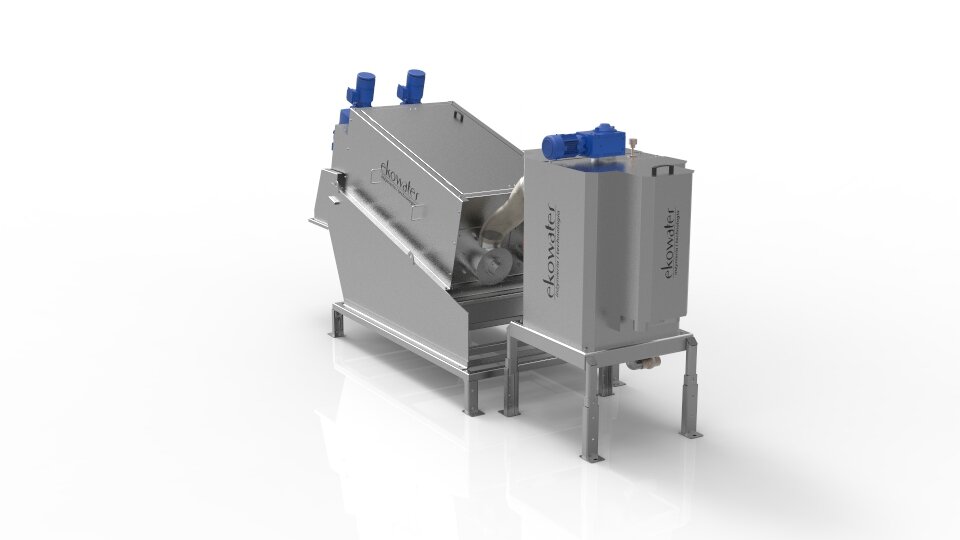

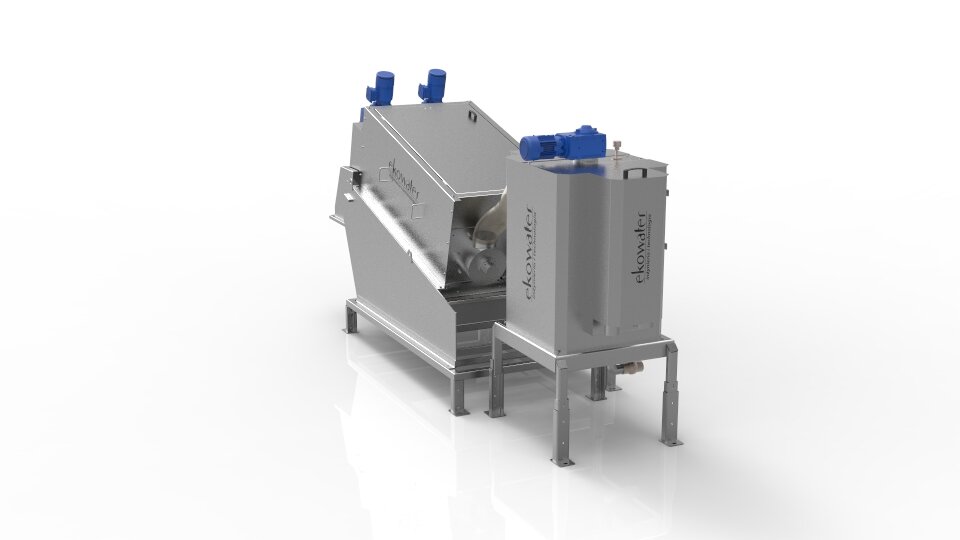

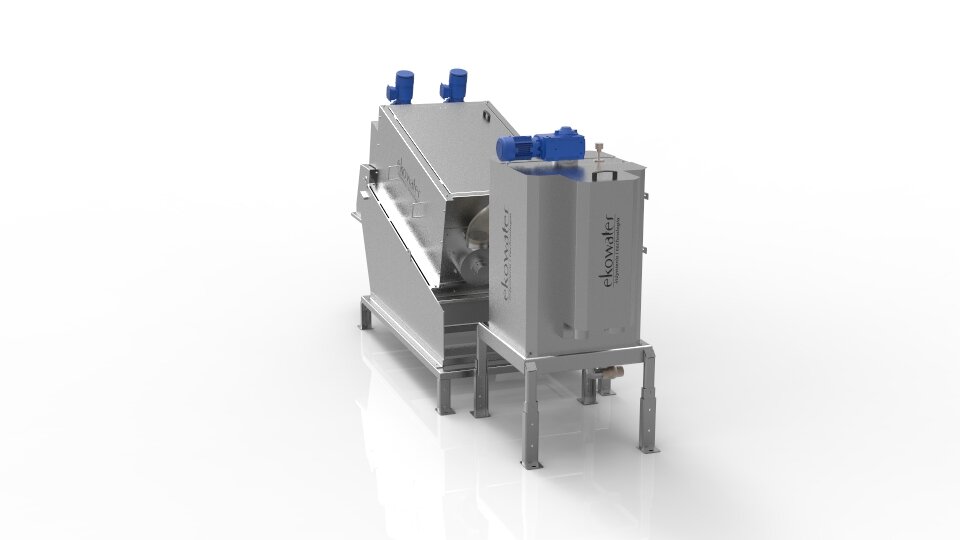

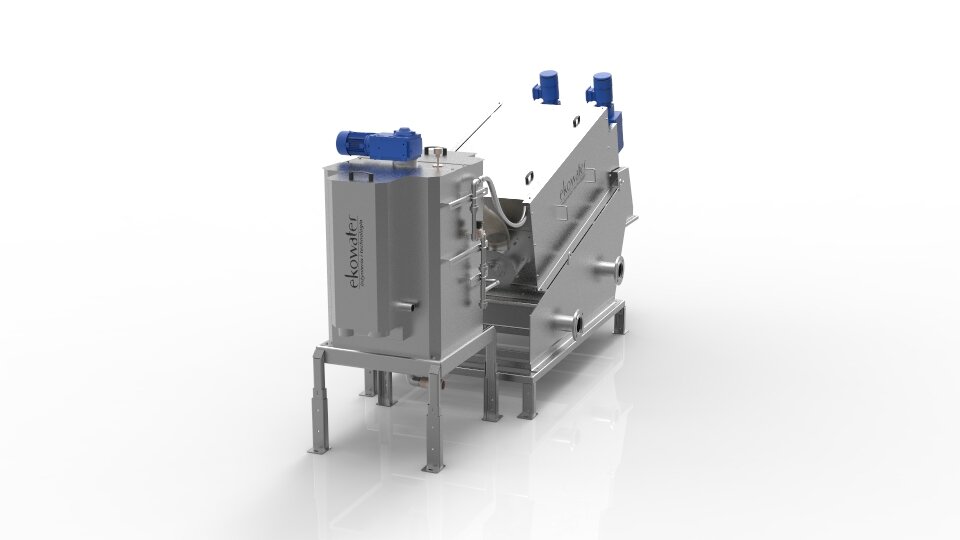

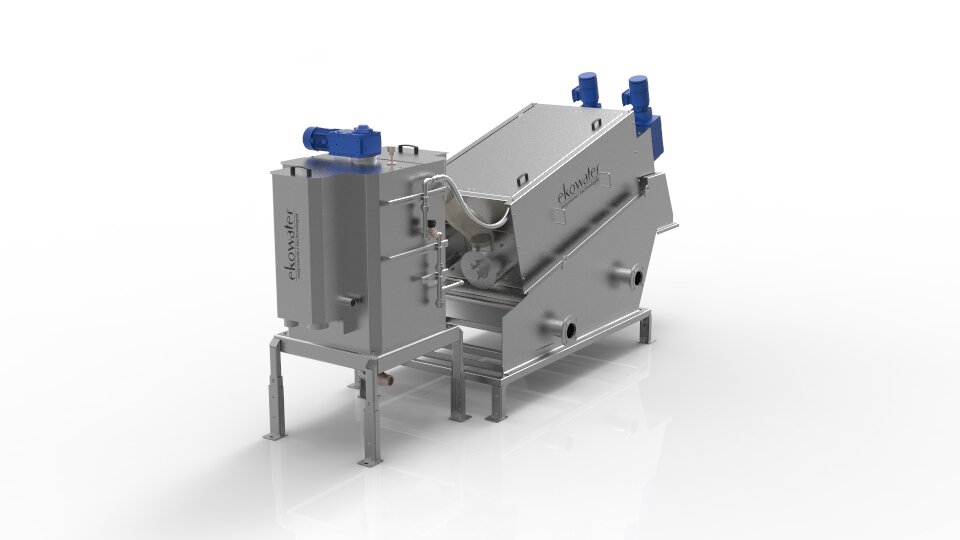

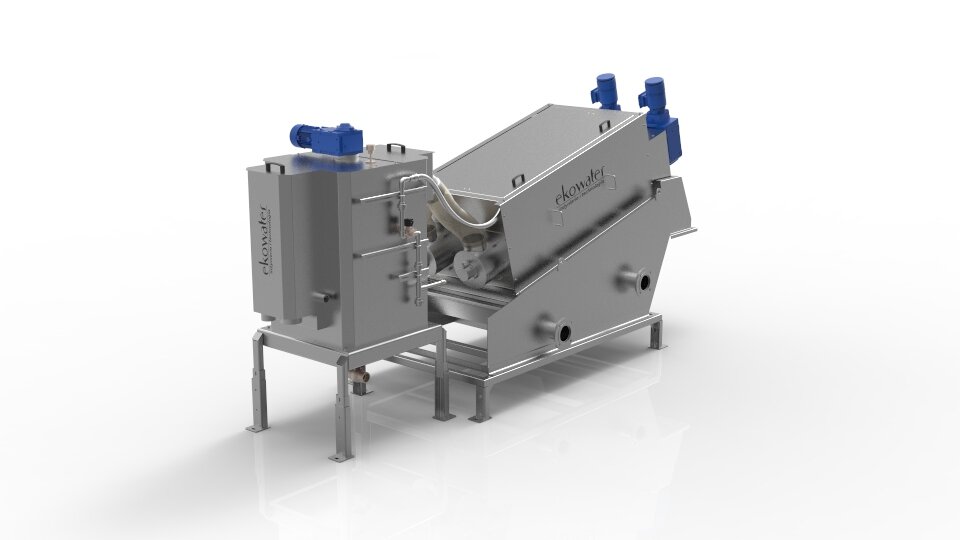

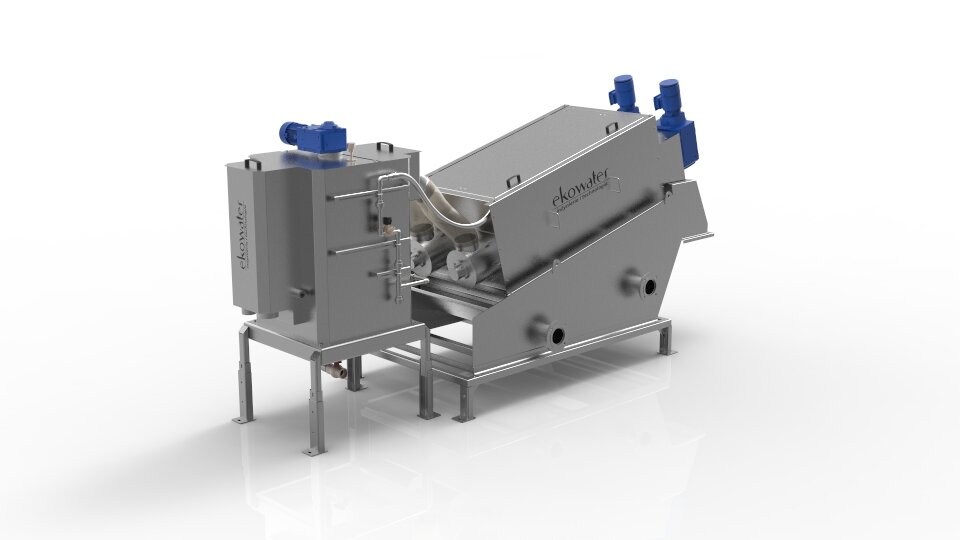

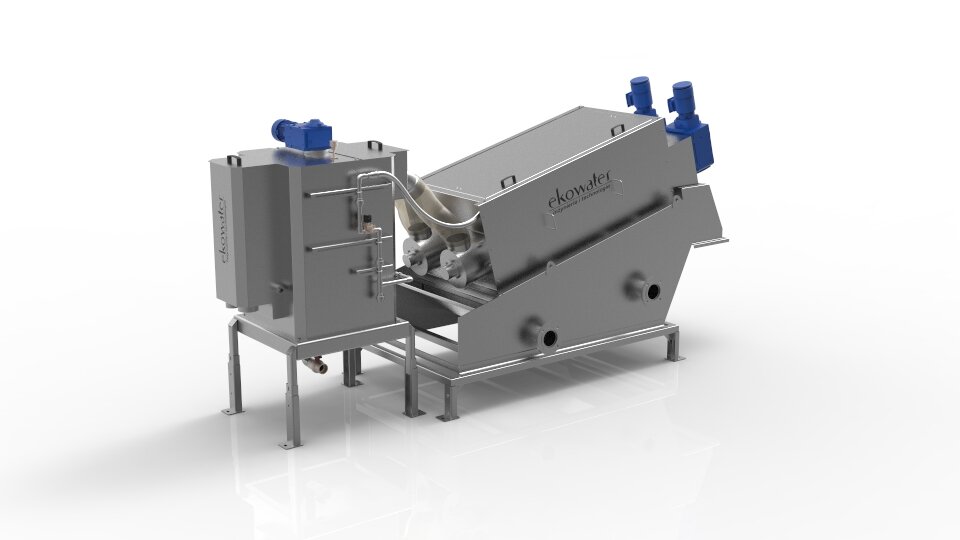

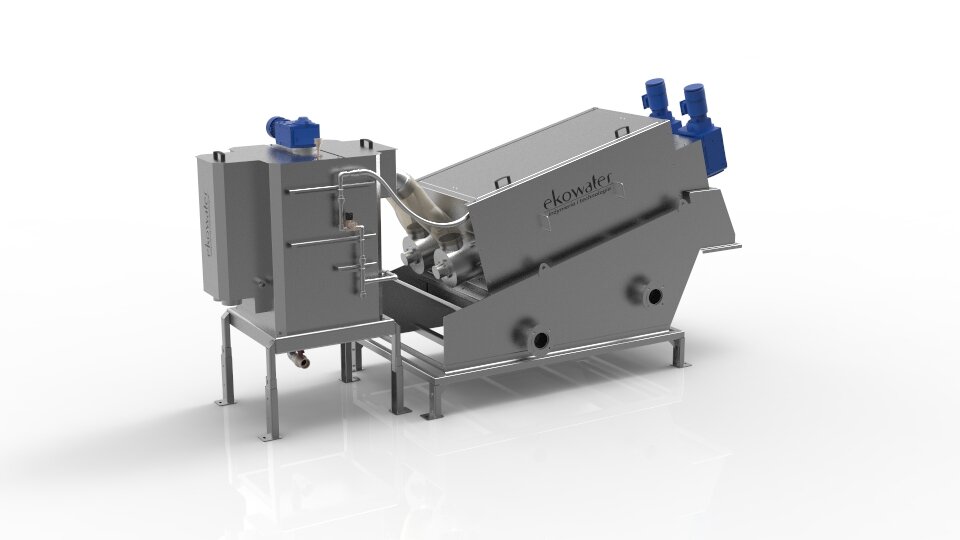

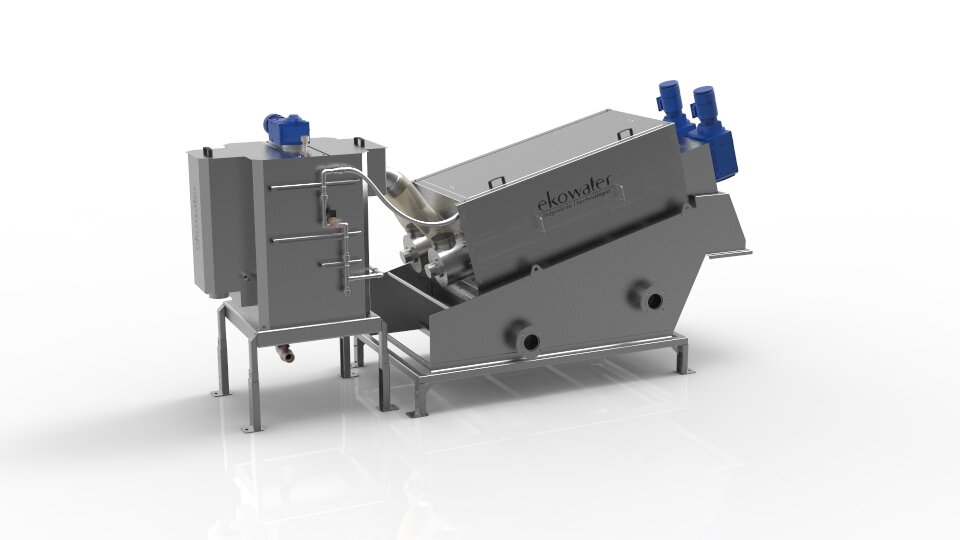

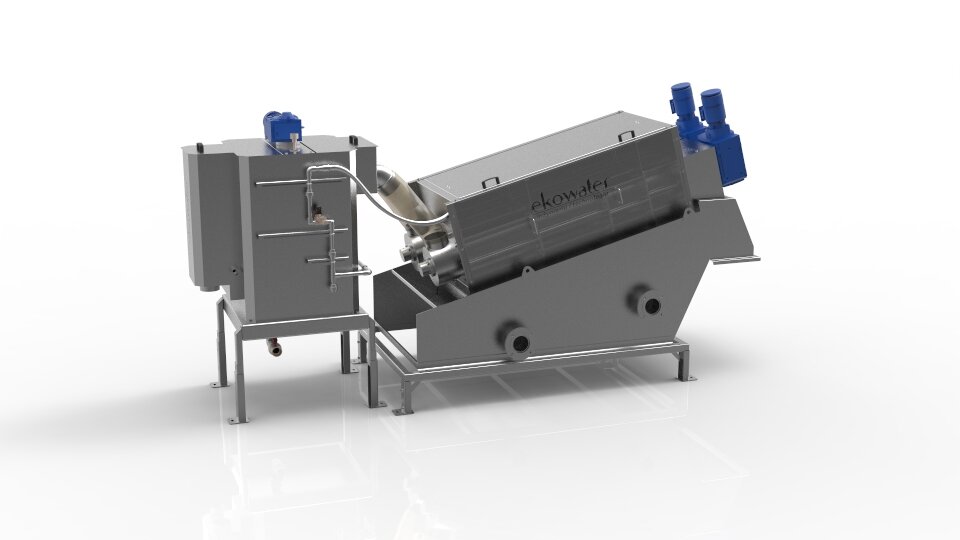

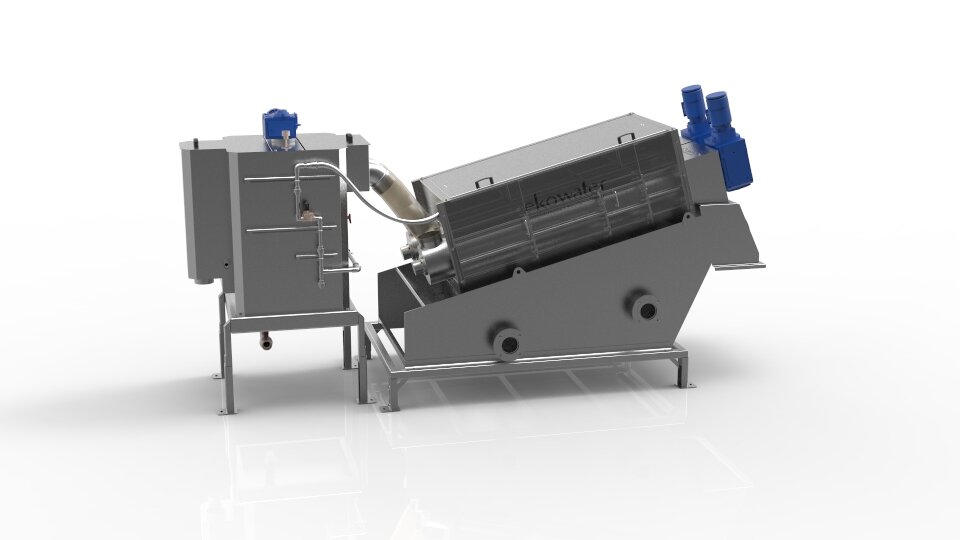

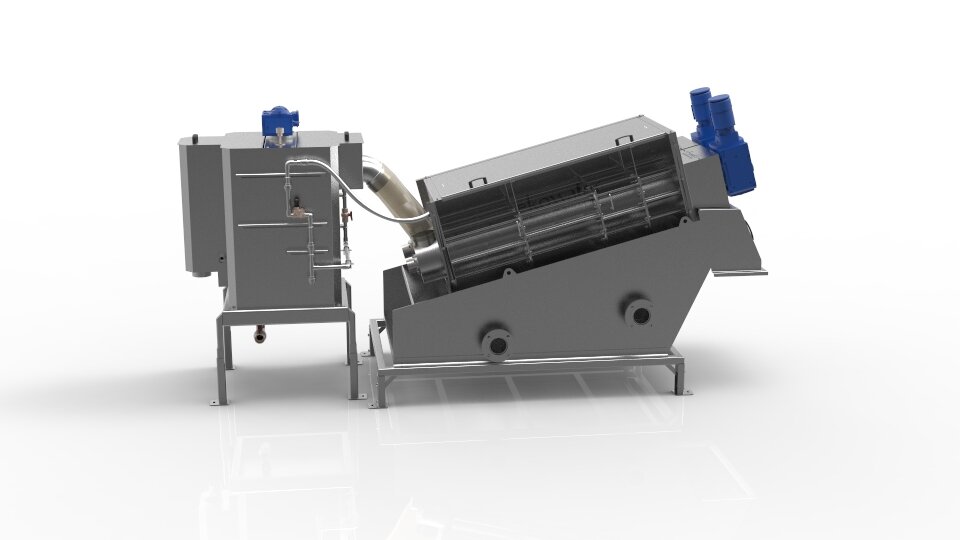

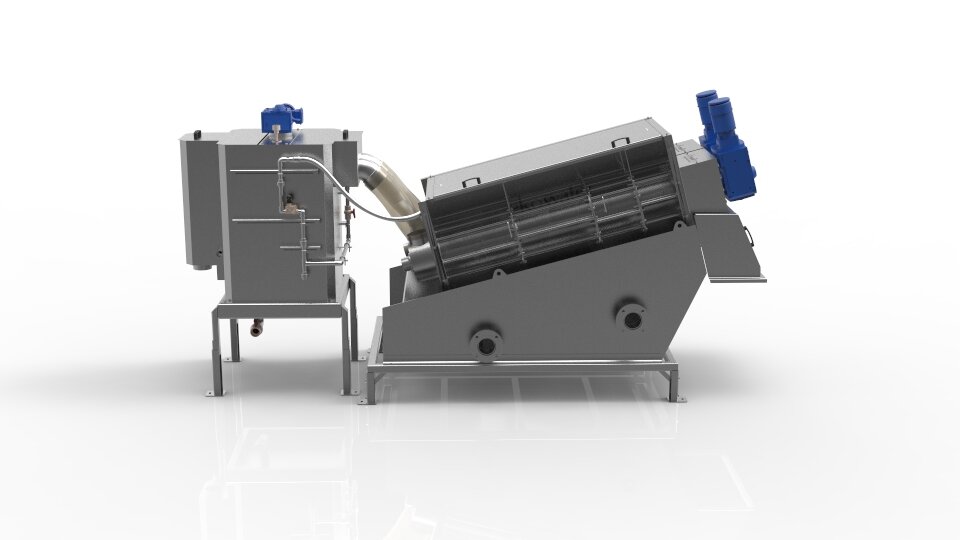

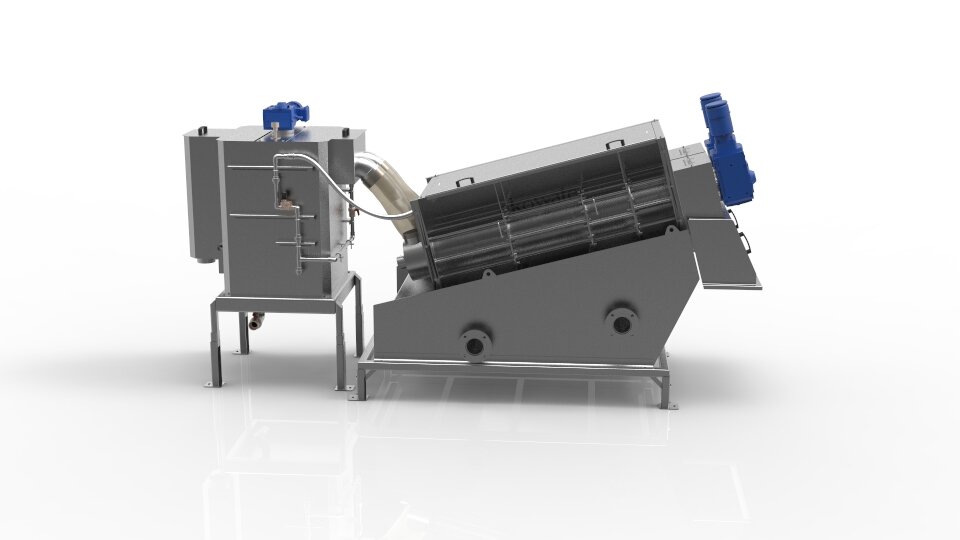

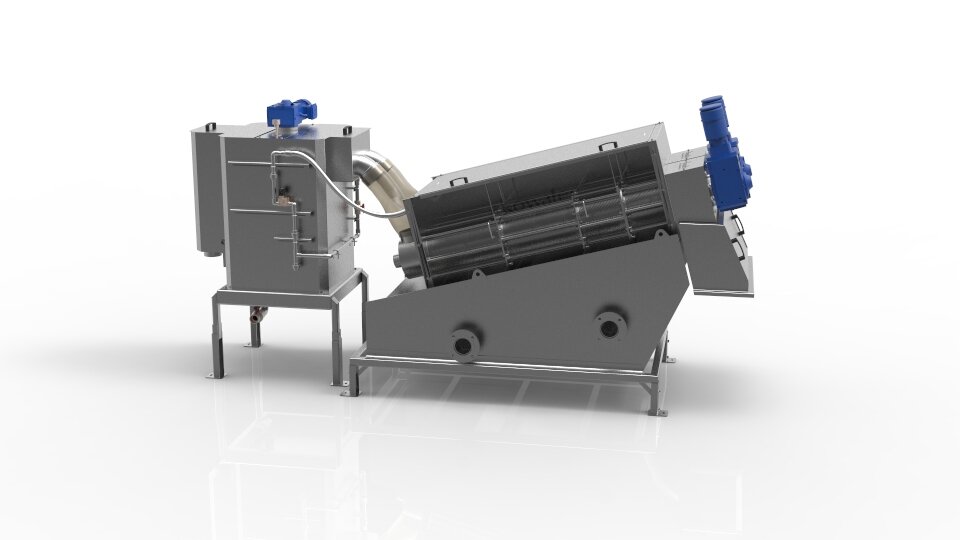

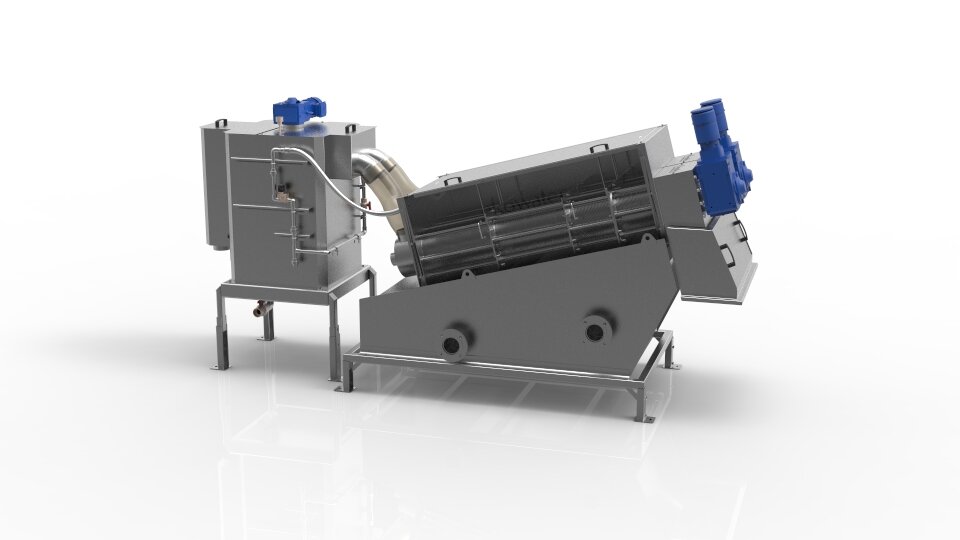

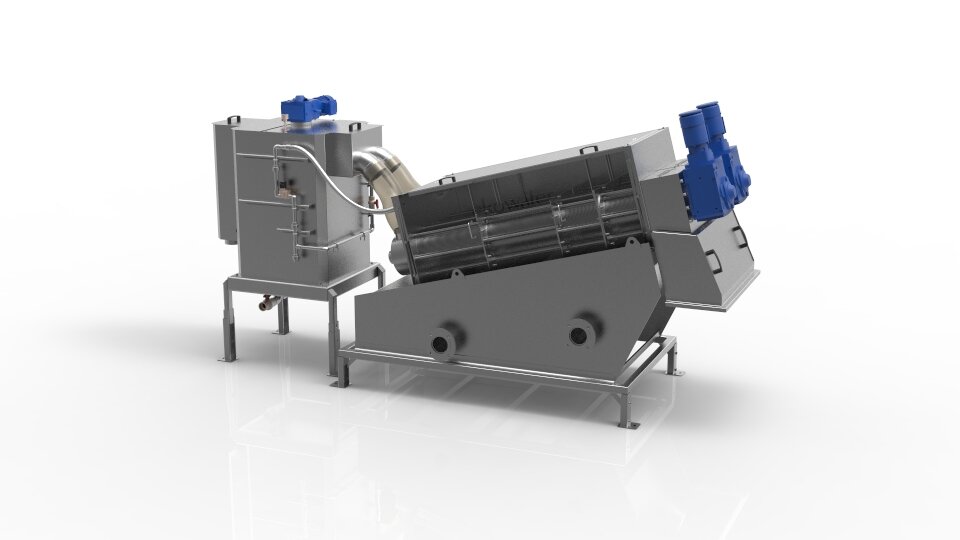

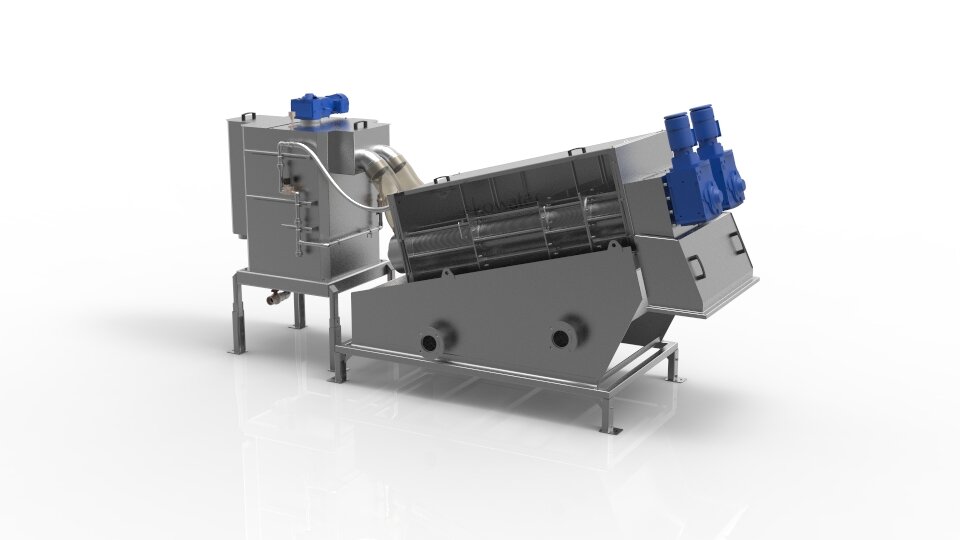

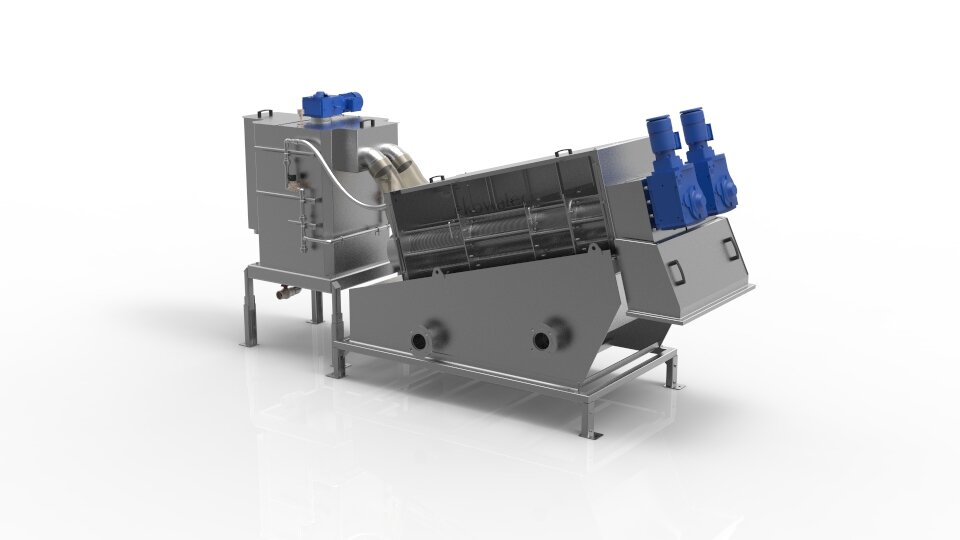

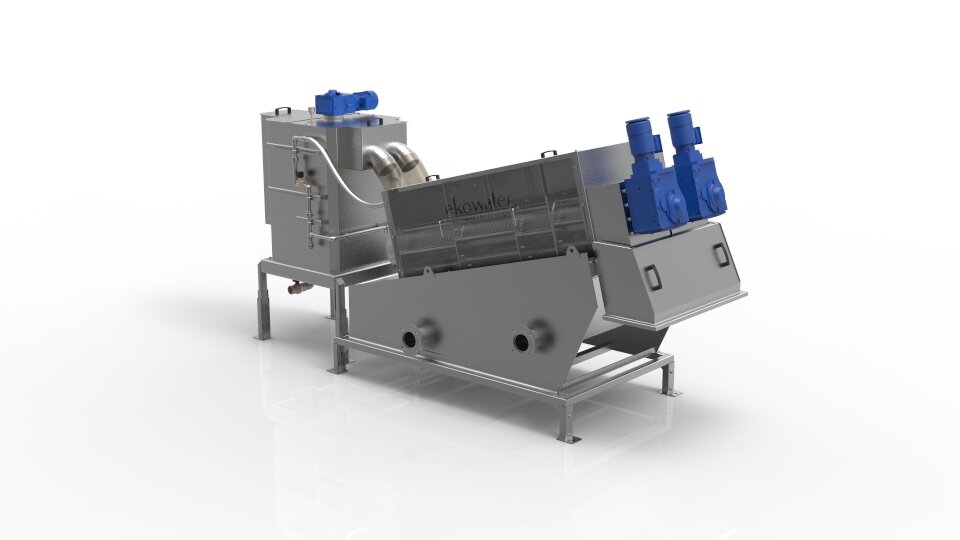

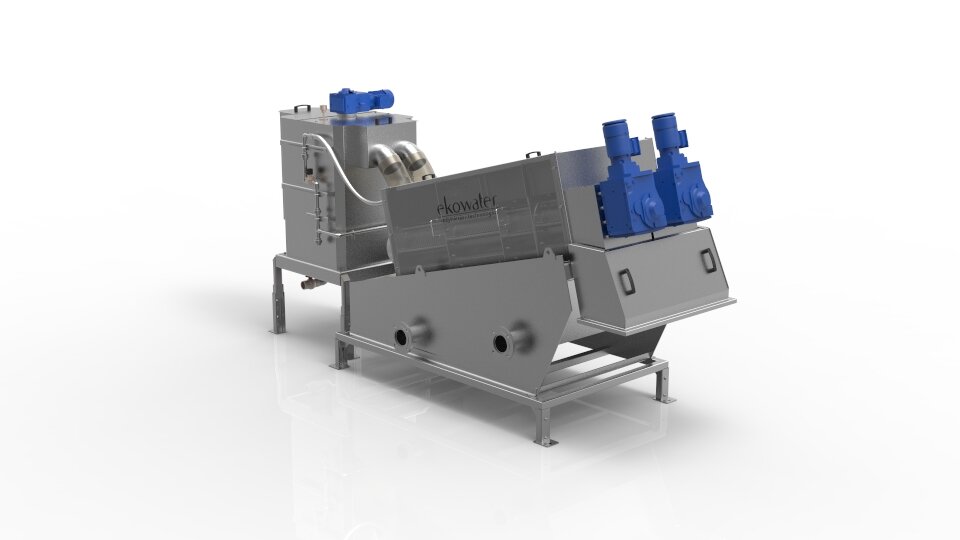

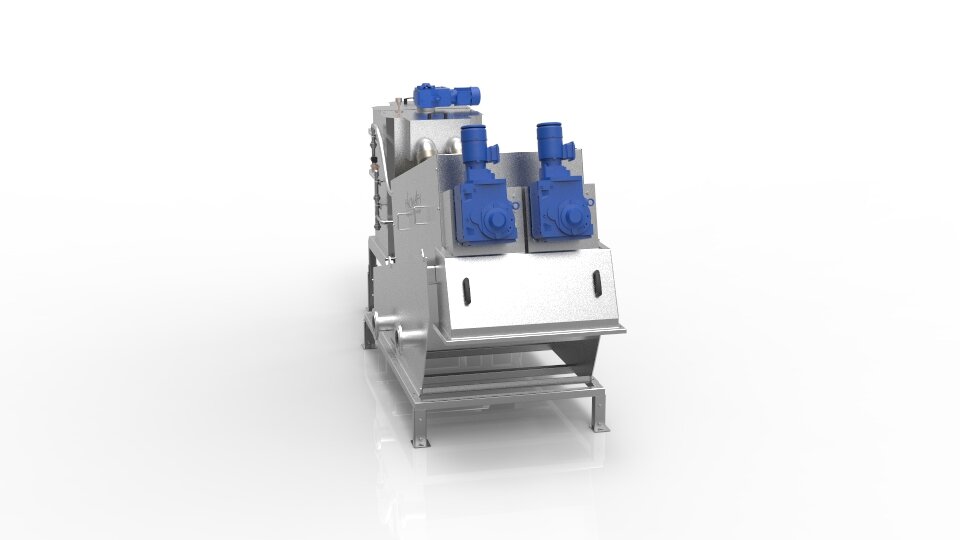

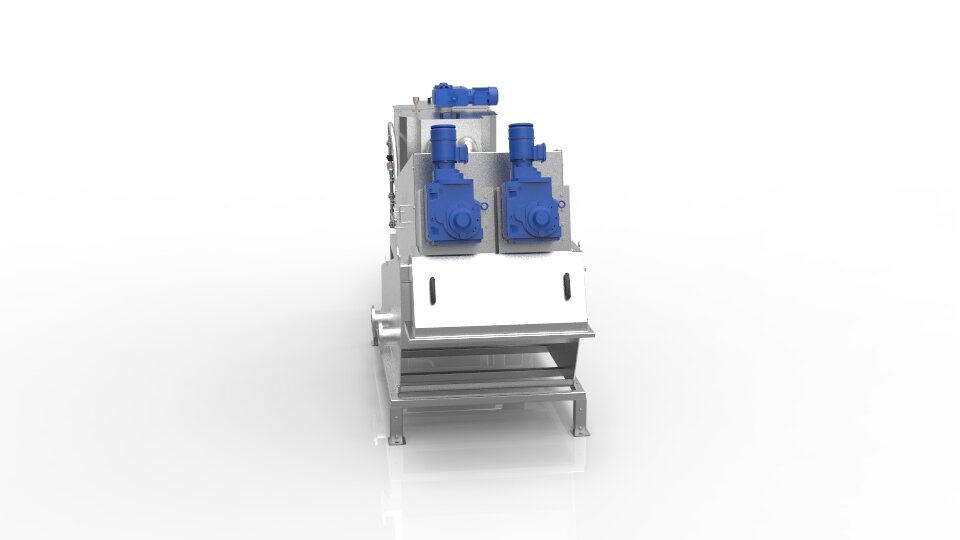

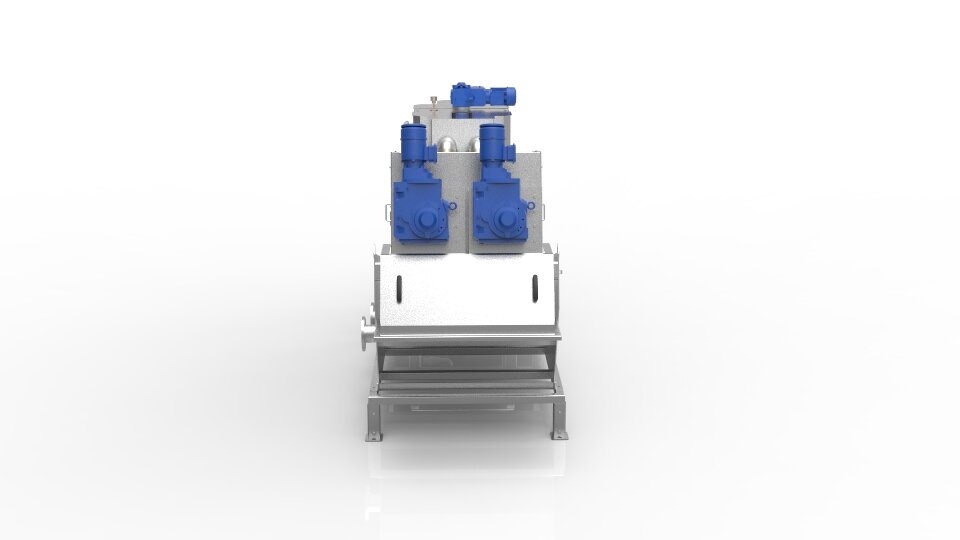

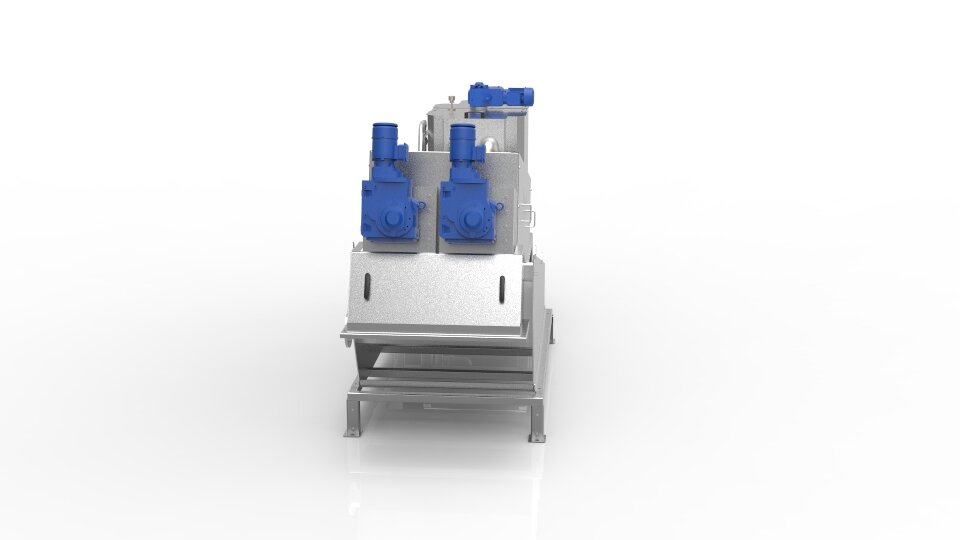

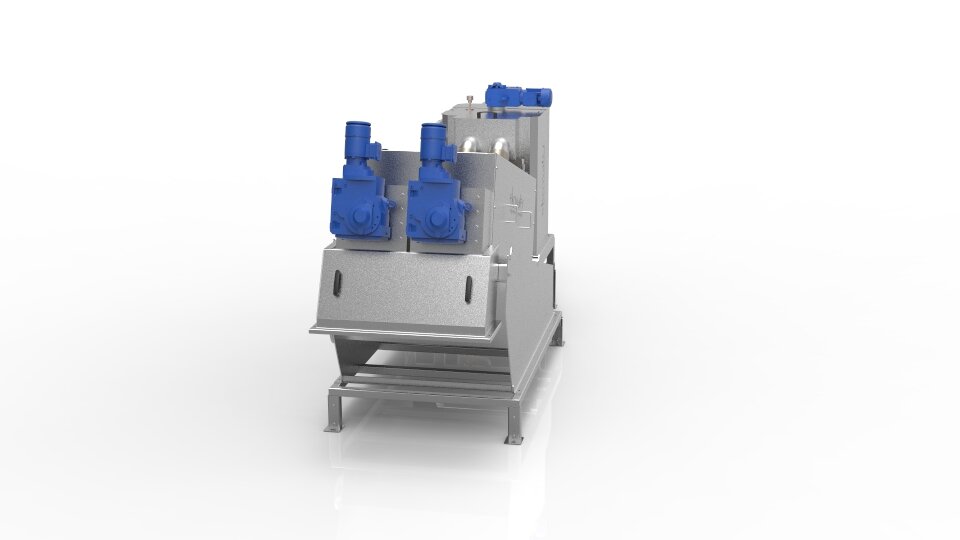

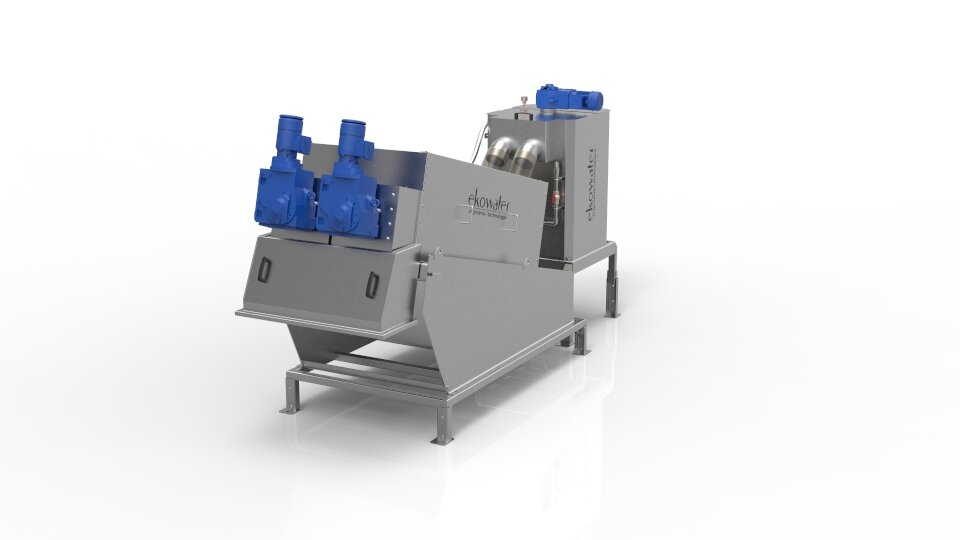

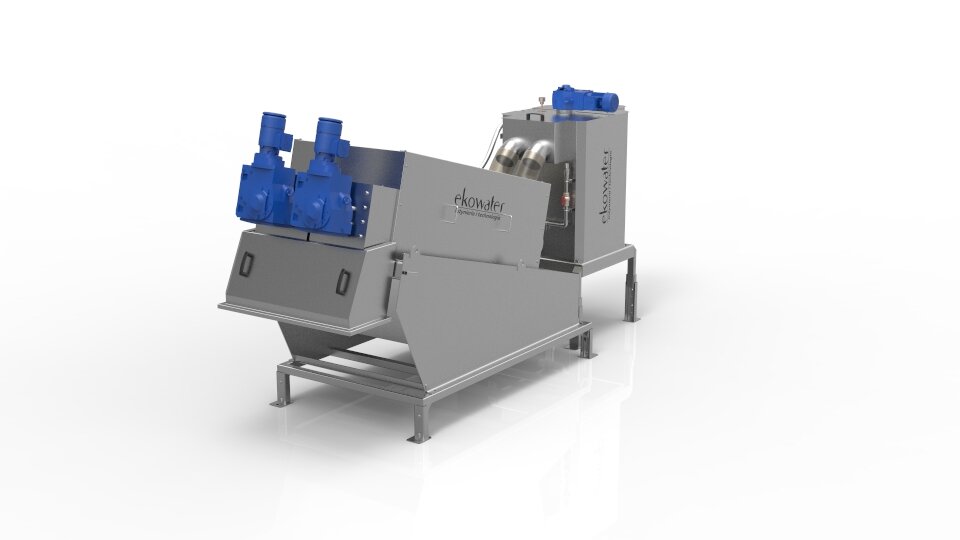

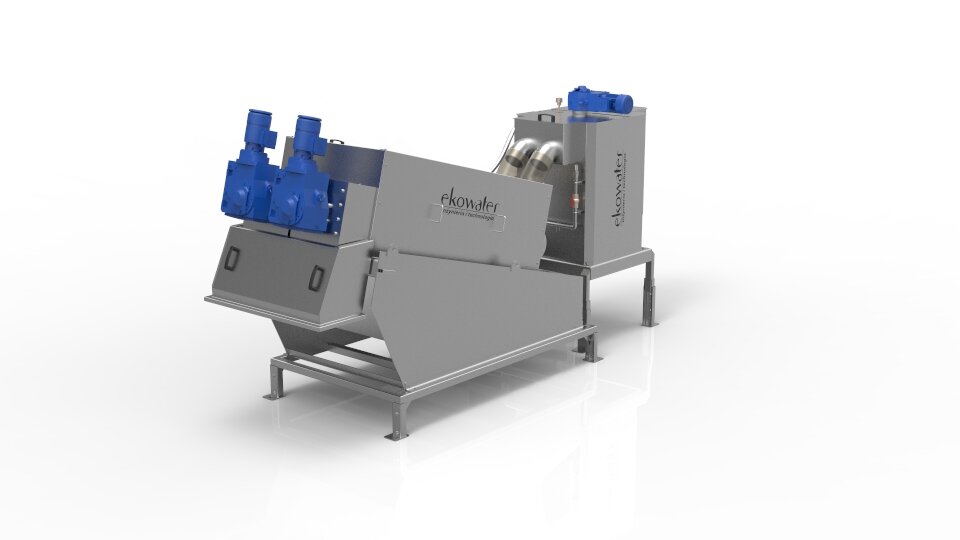

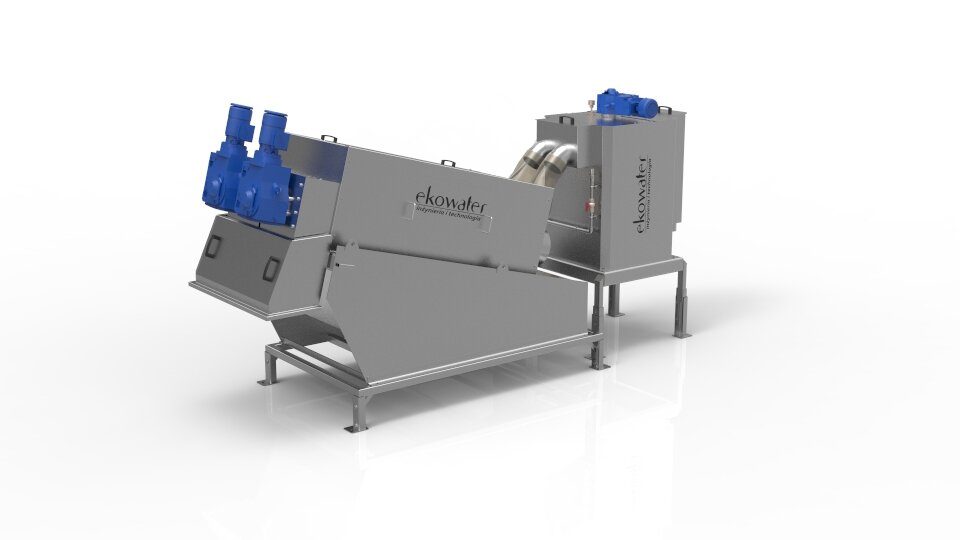

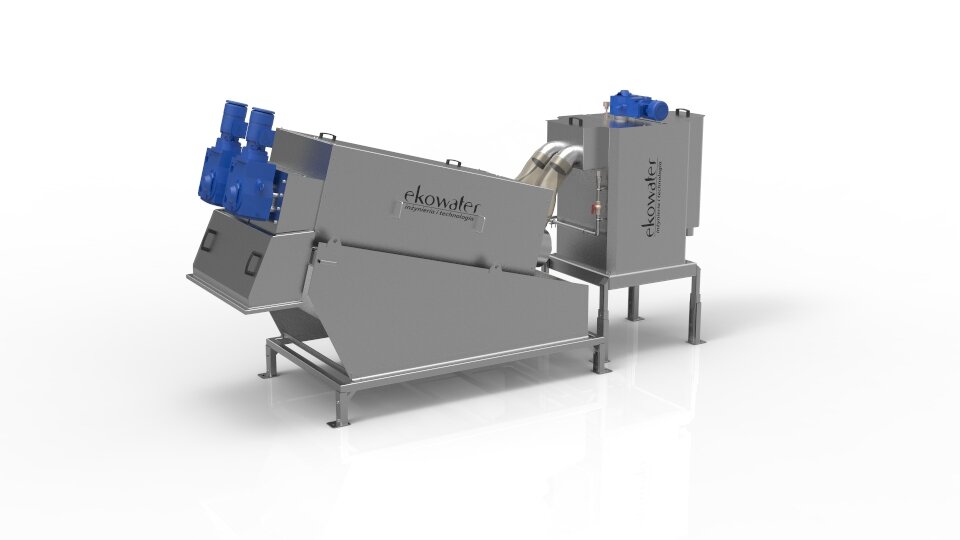

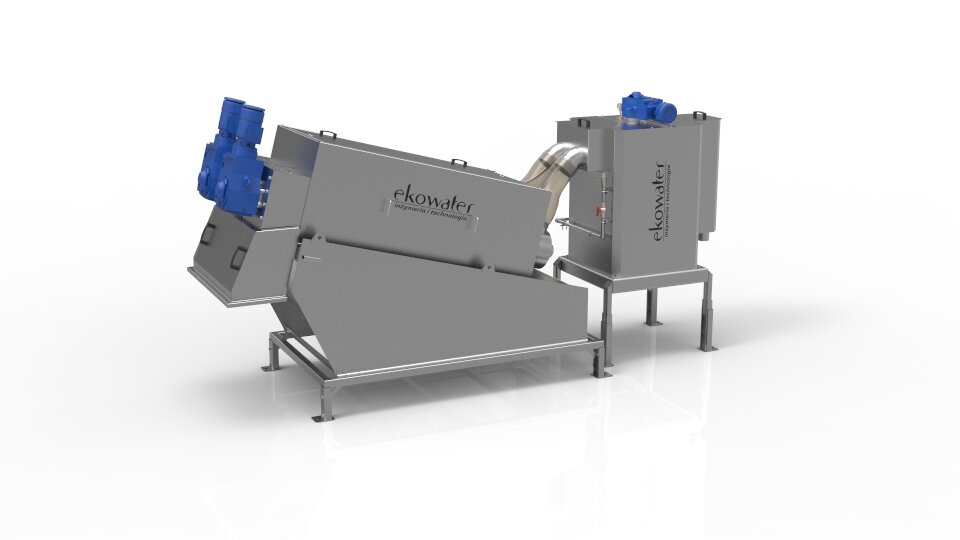

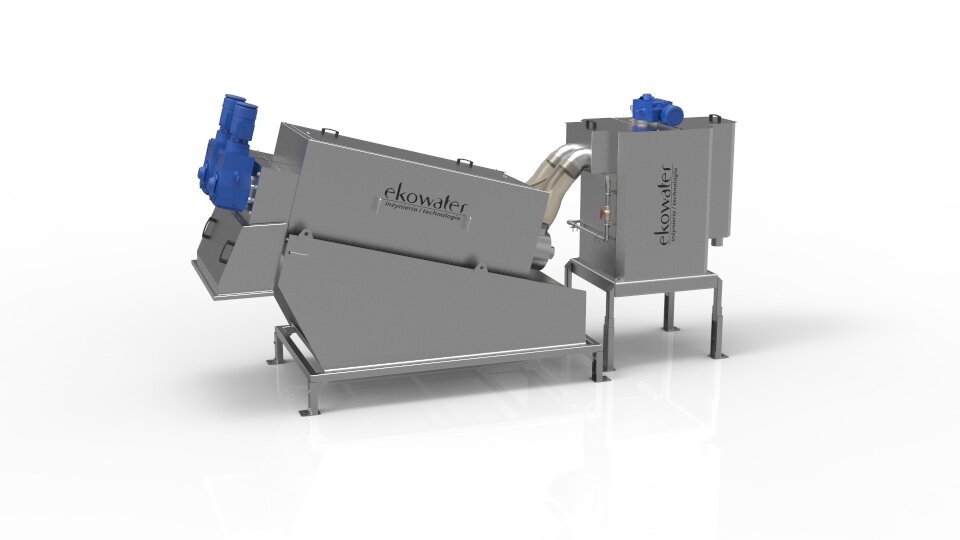

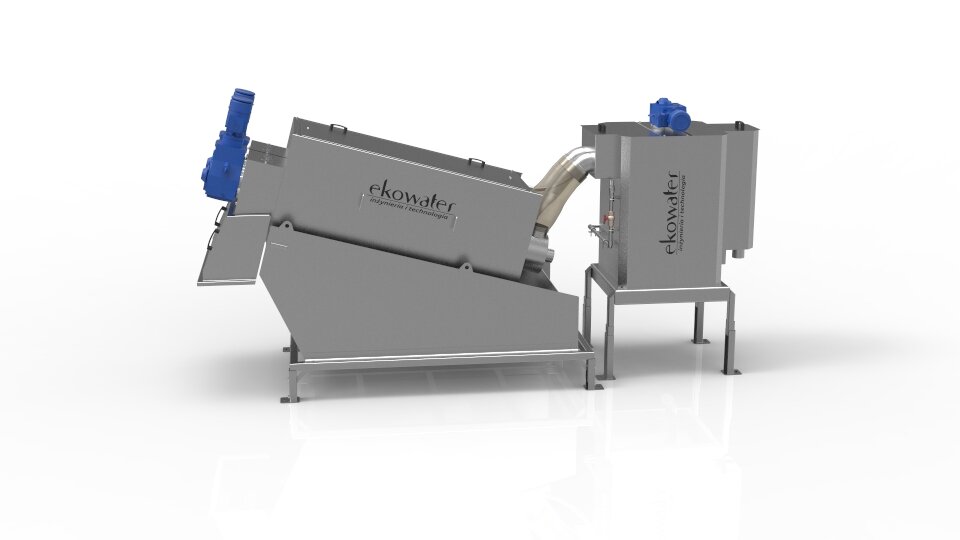

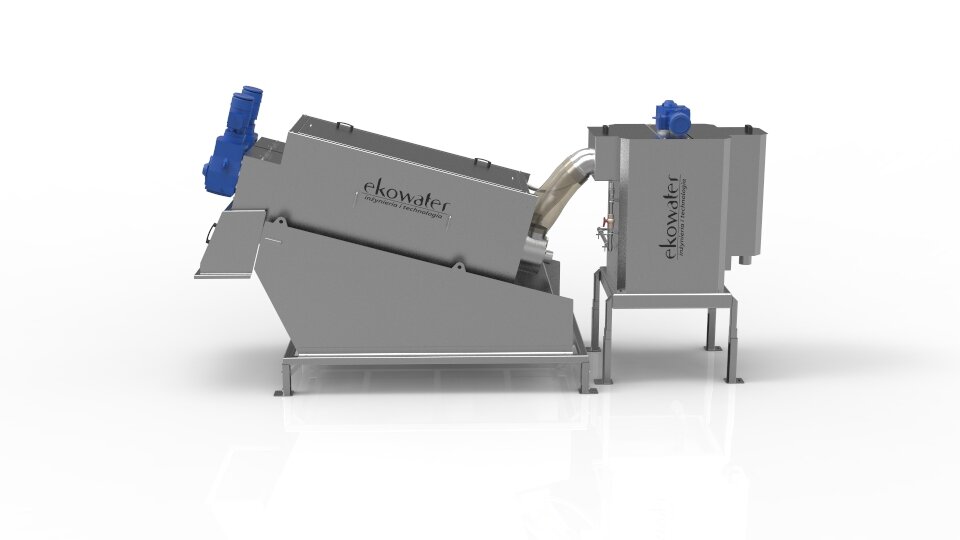

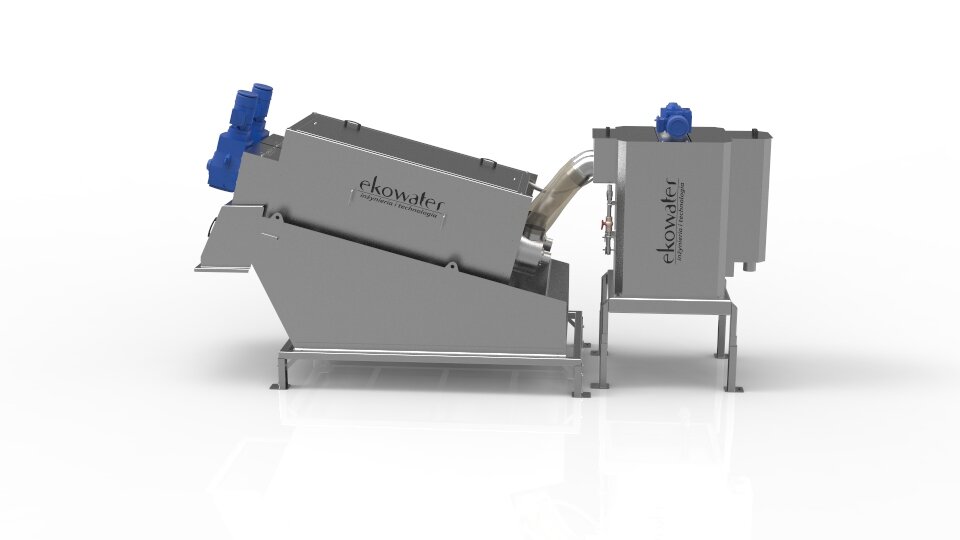

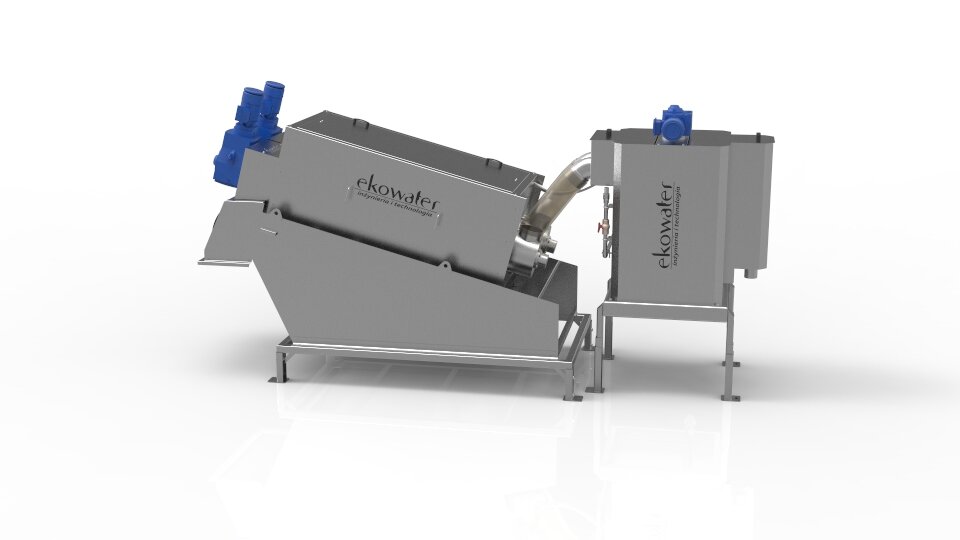

Ekowater’s multi-disc screw press is an innovative device used to dewater sludge left from the wastewater treatment. It can be utilized in both municipal and industrial sewage treatment plants. Our compact design takes less space than traditional devices for dewatering sludge. The press enables to drain sludge that is acquired directly from aeration chamber (bioreactor) or clarifier.

2

Operating principle

The device consists of two integral parts: flocculator and press. The agitator inside flocculator mixes sludge with flocculant, and flow velocity adjustment is responsible for the proper reaction time. Thoroughly mixed sludge is slowly transported by gravitation to the press where it is drained thanks to the screw inside the set of movable and fixed discs. Any modification in the width of the gap at the outlet changes the degree of sludge dewatering. If Buyer expresses such need, multi-disc screw press can be equipped with two-chamber flocculator and two rotating agitators. The implementation of divided leachate tank into two independent chambers allows to install leachate recycling system.

3

Advantages of multi-disc screw press

- the lowest operation costs in comparison with other devices for dewatering, such as belt press, screw press or centrifuge,

- no water consumption in the drainage process (water is used only for rinsing the disc to keep the press clean)

- the lowest energy consumption,

- the lowest noise emission level

- compact size

- no need for the use of compressed air

5

Capacity

The capacity of Ekowater’s multi-disc screw press reaches from 5 to 640 kg/h s/m

7