Purpose

Suspended decanter

Sewage pumping stations and their equipment

Purpose

Suspended decanter

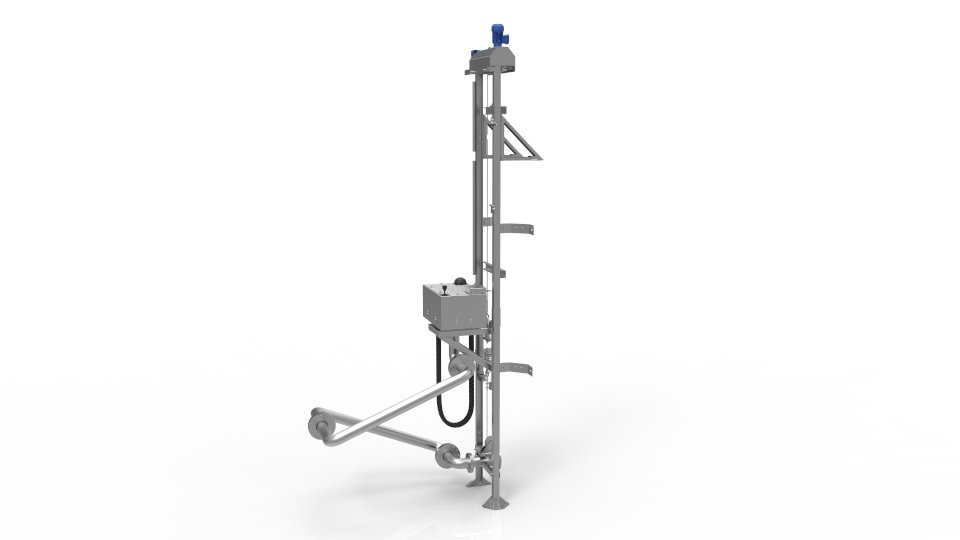

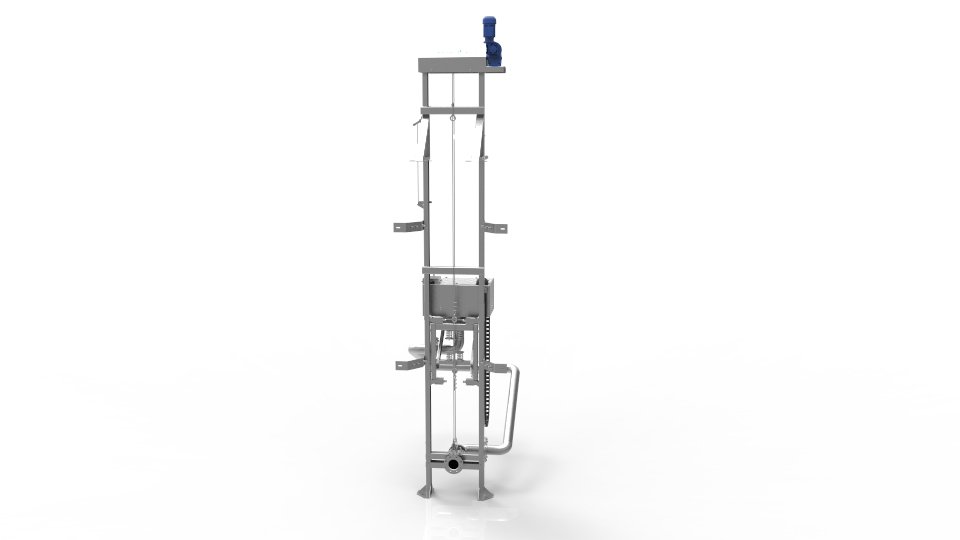

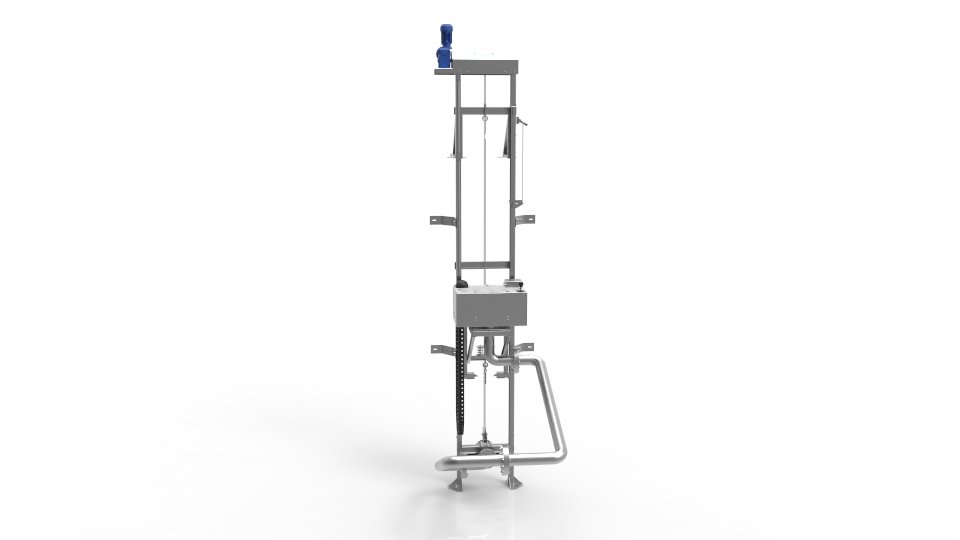

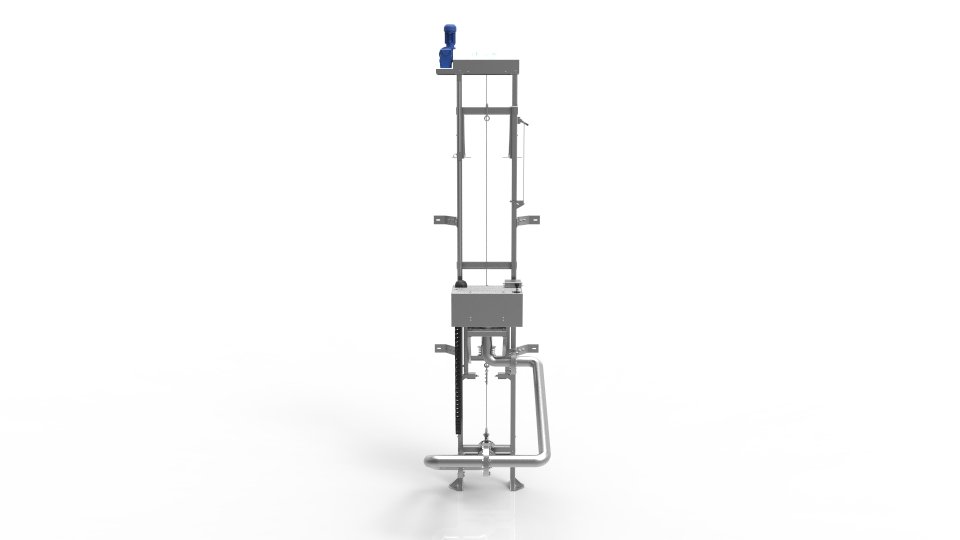

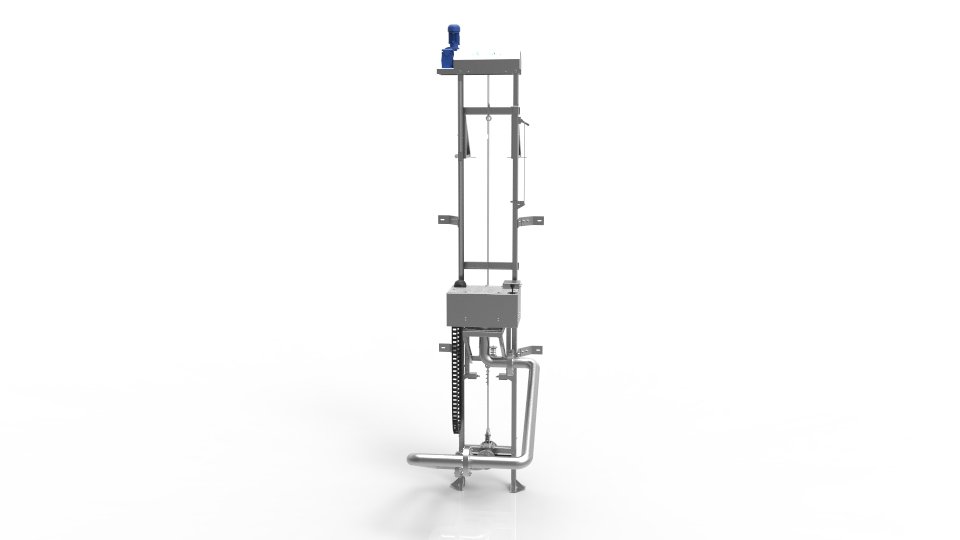

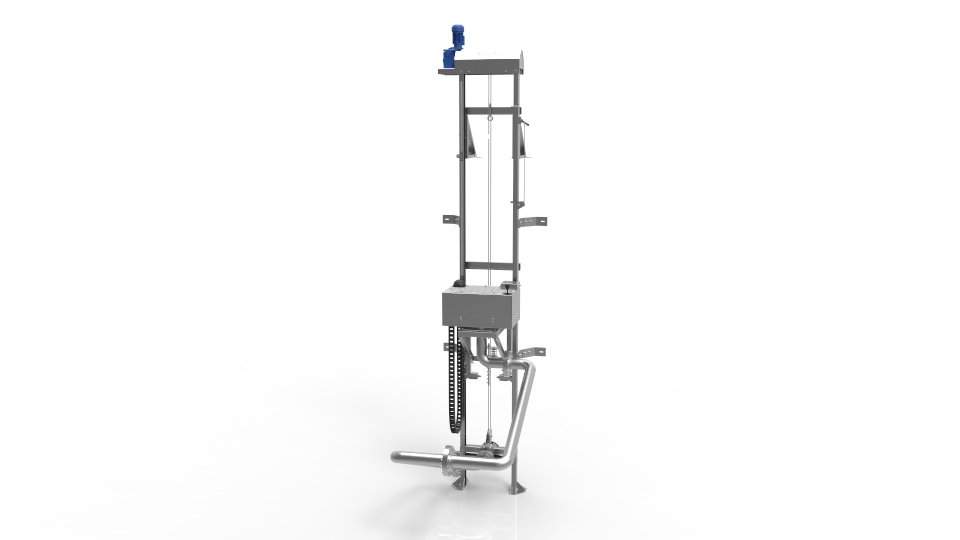

Ekowater’s suspended decanter is used for removal of supersedimentary sewage through the internal hopper. The device may be used in both domestic and industrial sewage treatment plants. Due to its design, the device is maintenance-free, and its construction ensures long service life expectancy.

Operating principle

A decanter unit is installed on guide rails that are attached to the walls of the tank. The device moves vertically and its immersion is regulated by the cable connected to a cart that is propelled by the motor reductor from above the bridge.

Decanter’s optimum capacity is reached by sustaining constant immersion level of hopper’s overflow rim. A level sensor regulates how deep overflow rim is immersed. The fluid flows through the pipeline by gravity and passes three maintenance-free rotating unions also made of stainless steel. Tightly sealed unions enable free, linear movement of the decanter in the tank.

The drive system is able to lift the device automatically to the maintenance level – above sewage surface – so the technical condition of the device could be assessed and maintenance work done.

Advantages of the suspended decanter

The device is produced by the company certified by: ISO 9001, PN-EN 1090-2 and ISO 3834-2

Material

Duplex stainless steel AISI 304, AISI 316

Capacity

The capacity of Ekowater’s suspended decanter reaches between 0 m3/h to 400 m3/h maximum.

EW-40DK – capacity 40 m3/h

EW-100DK – capacity 100 m3/h

EW-220DK – capacity 220 m3/h

EW-400DK - capacity 400m3/h