Surface scrubber effluent

Back to the offer |

Sewage pumping stations and their equipment

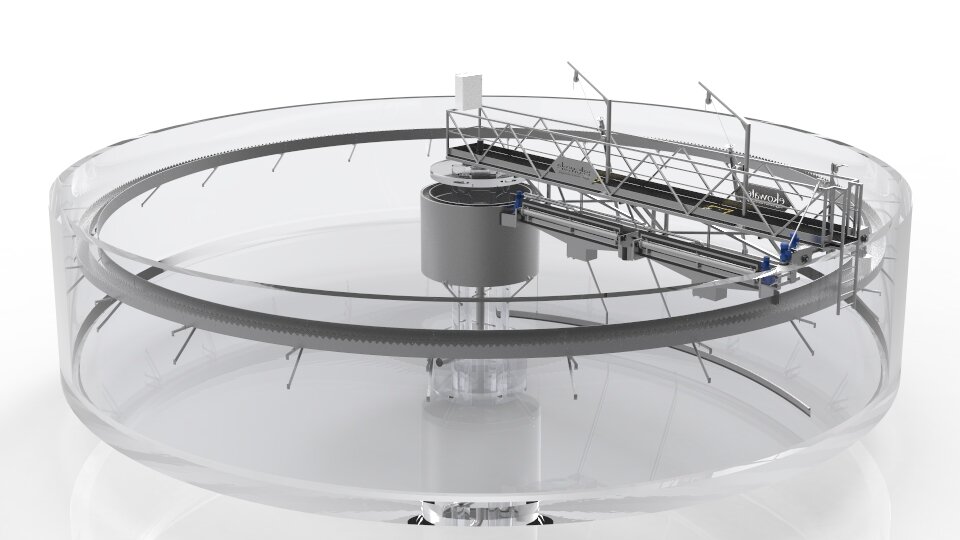

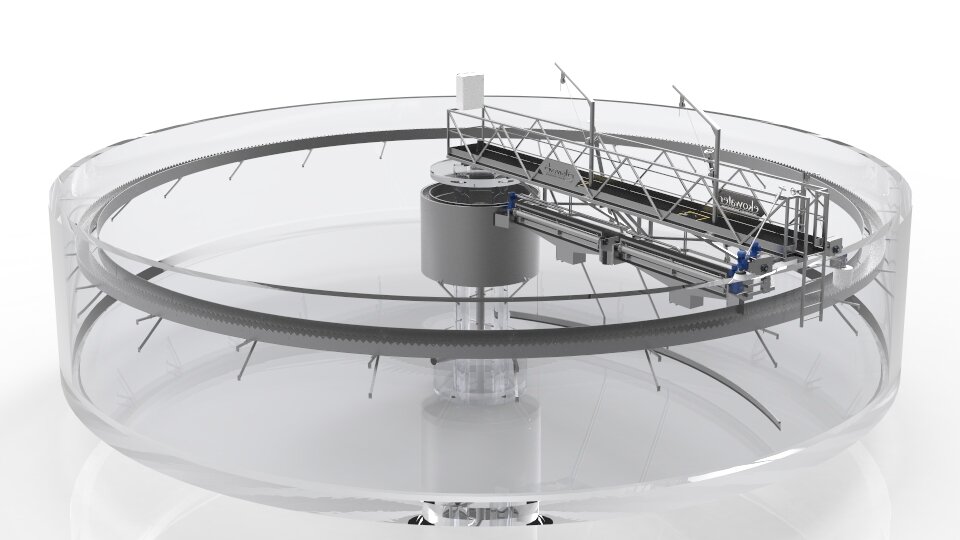

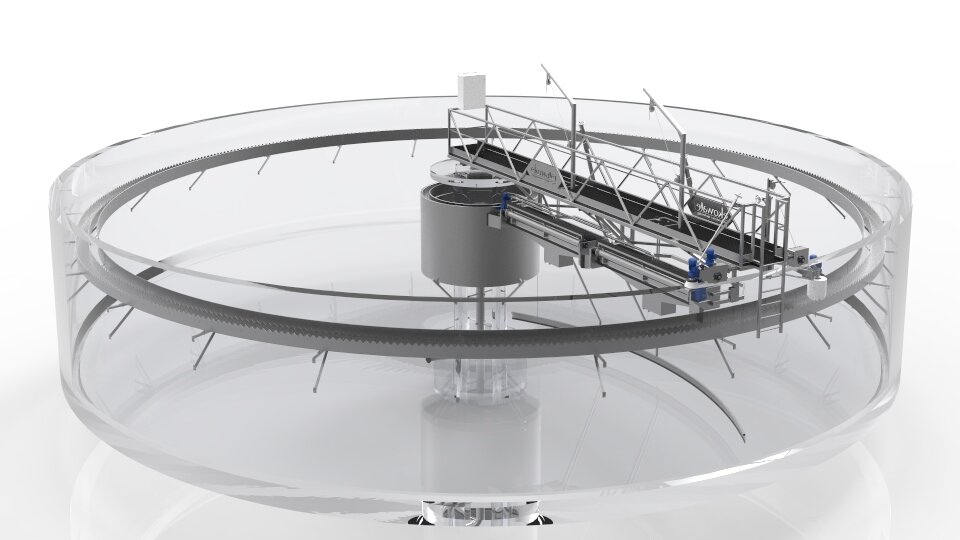

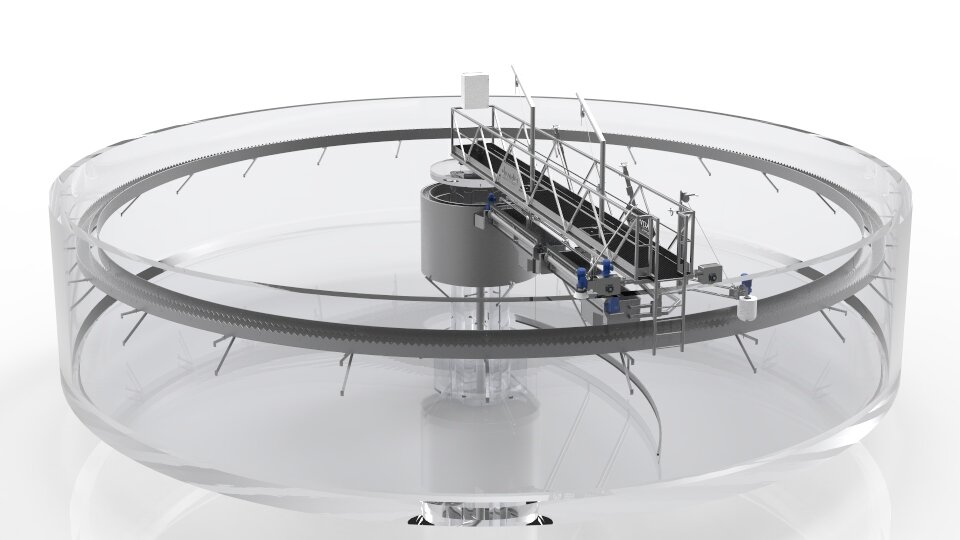

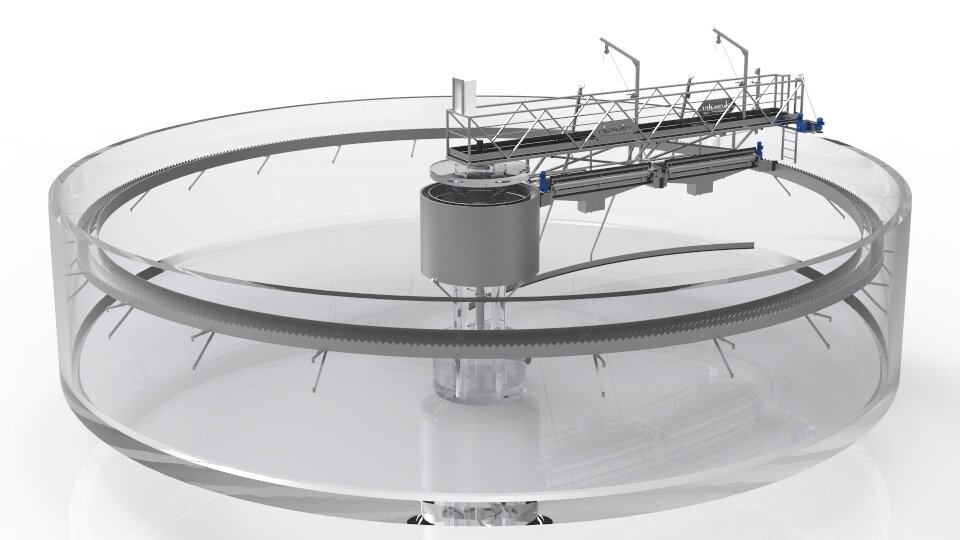

Surface scrubber effluent

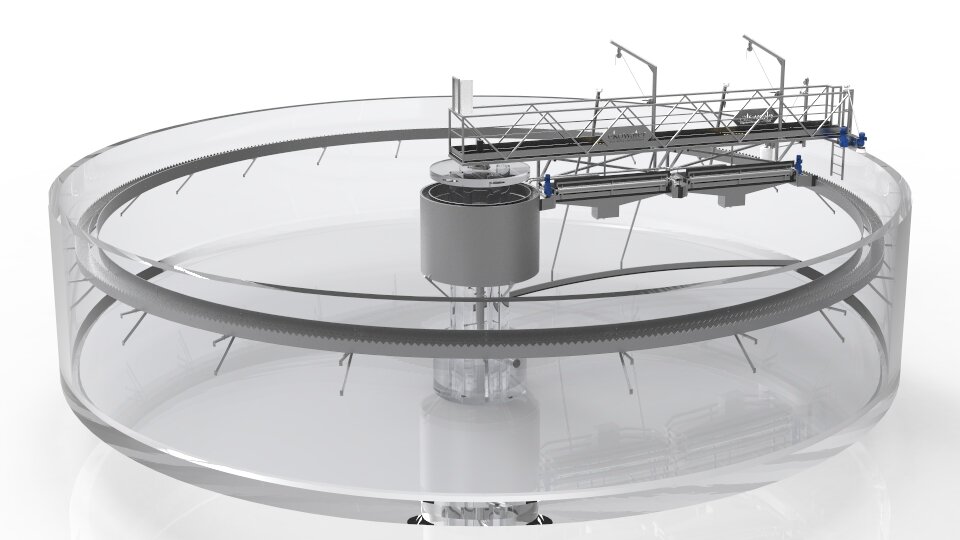

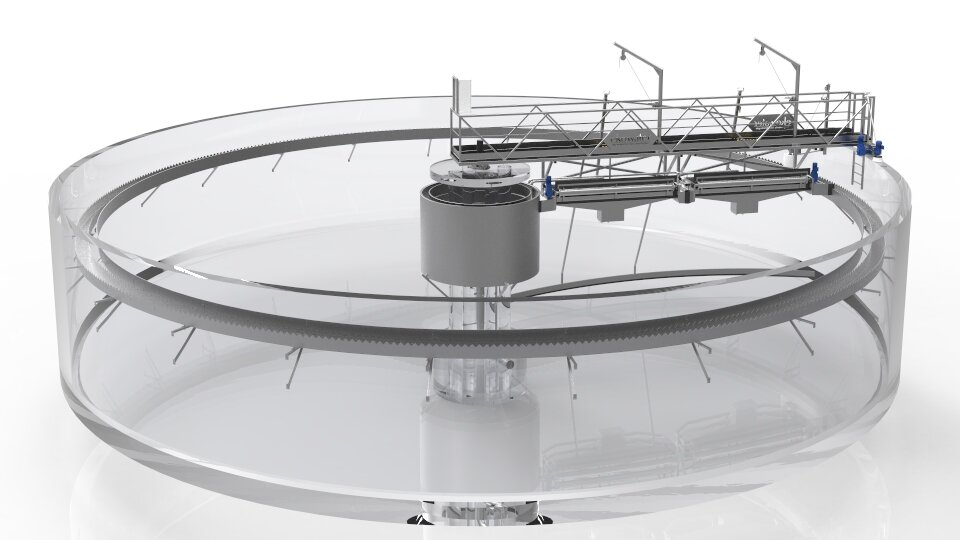

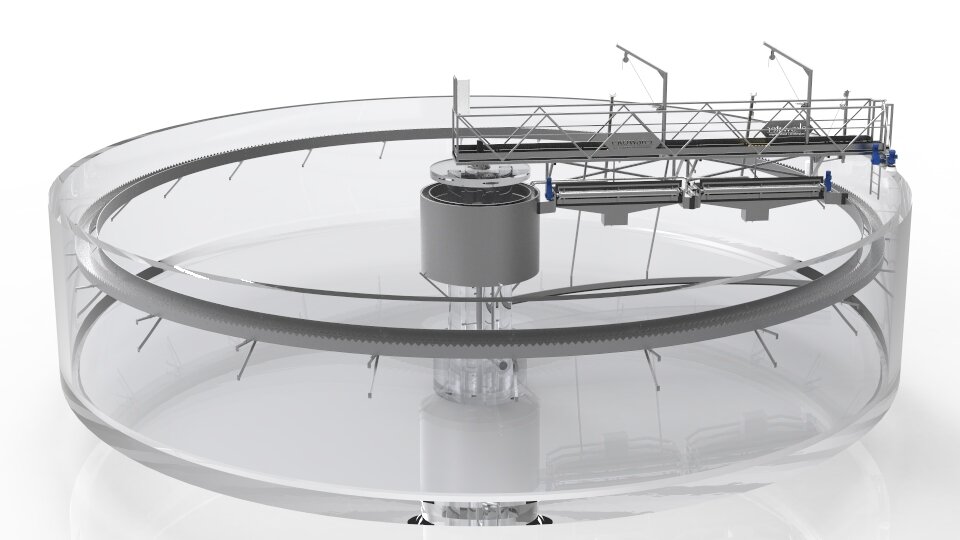

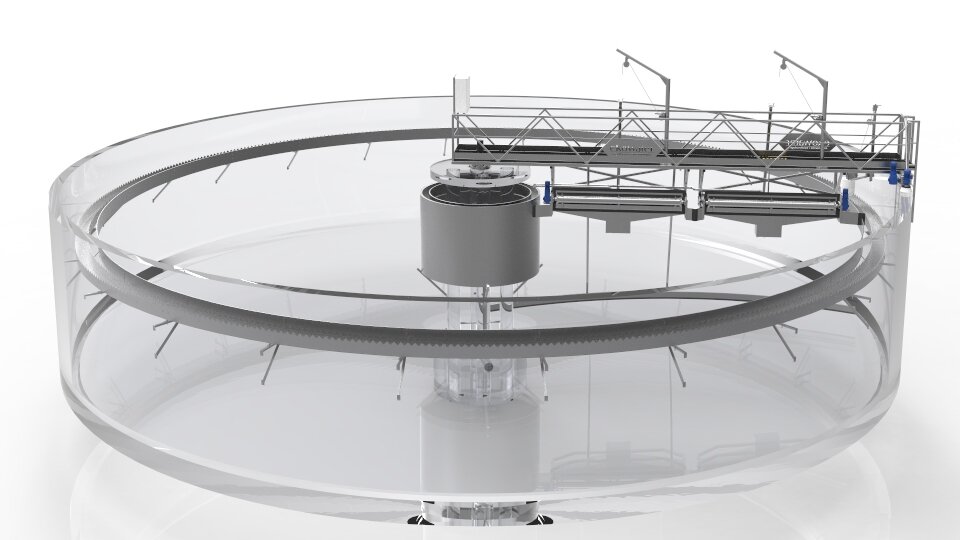

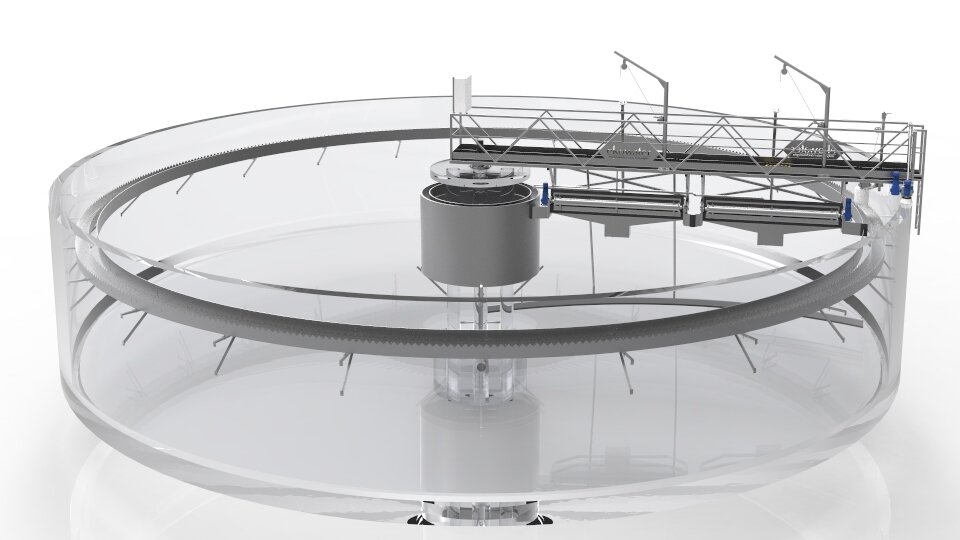

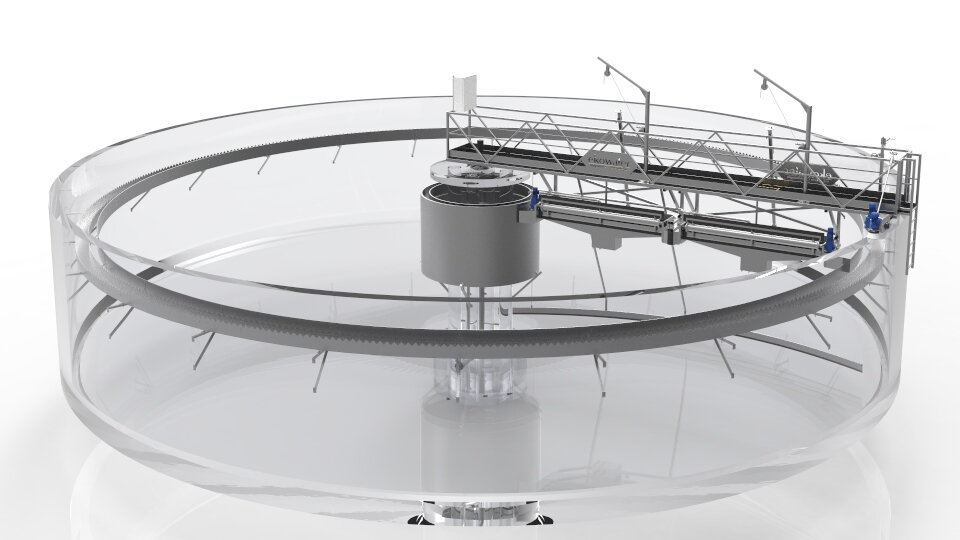

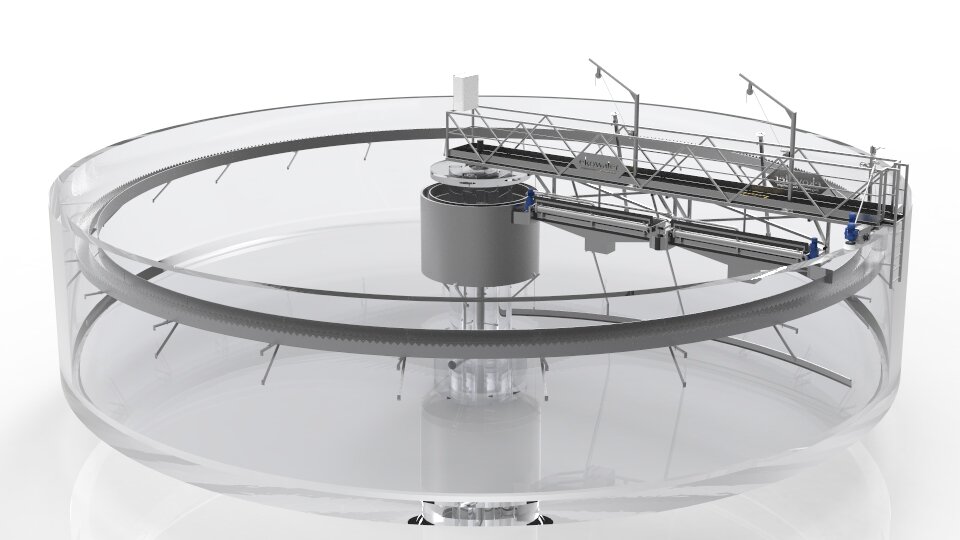

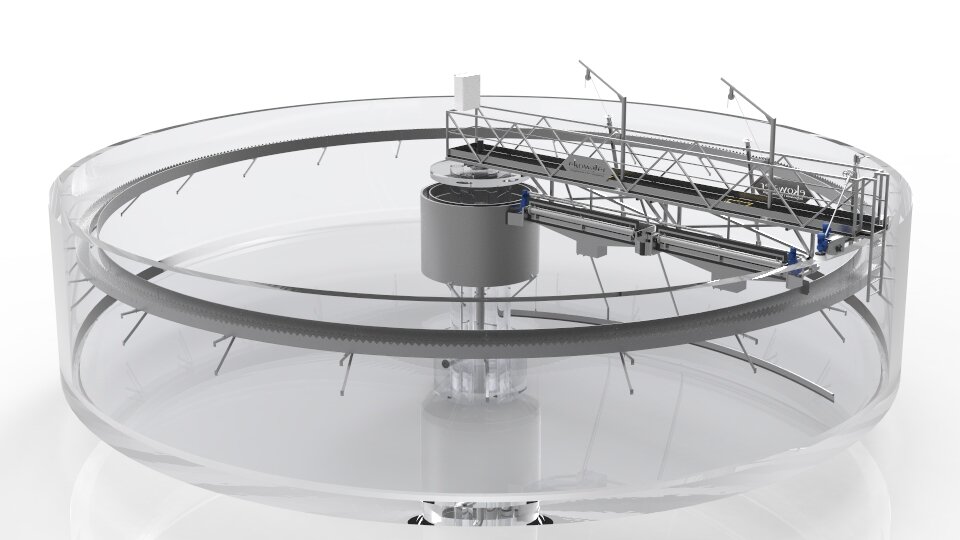

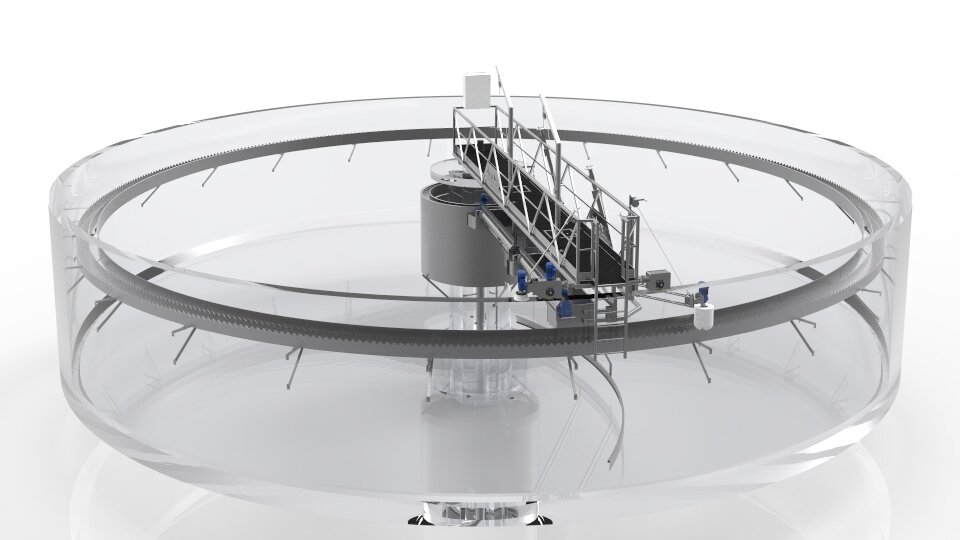

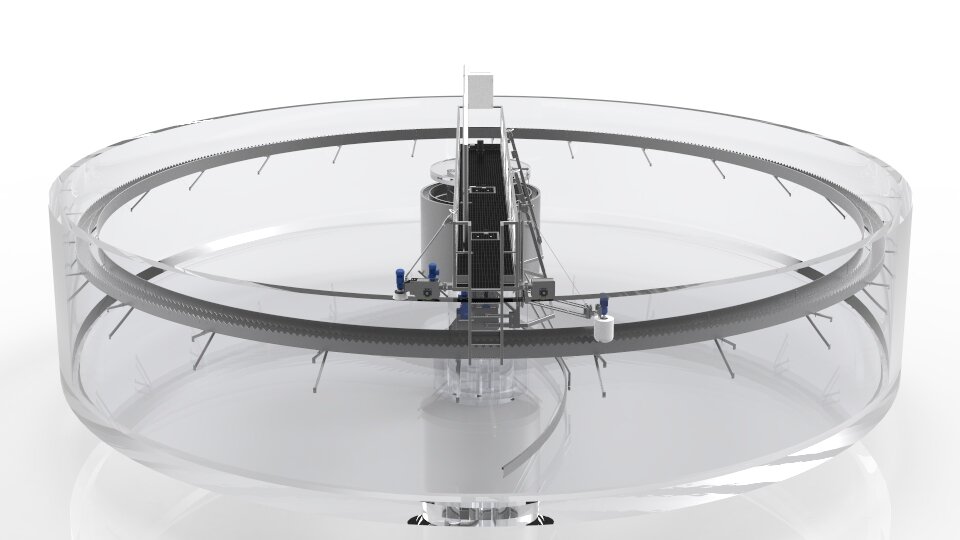

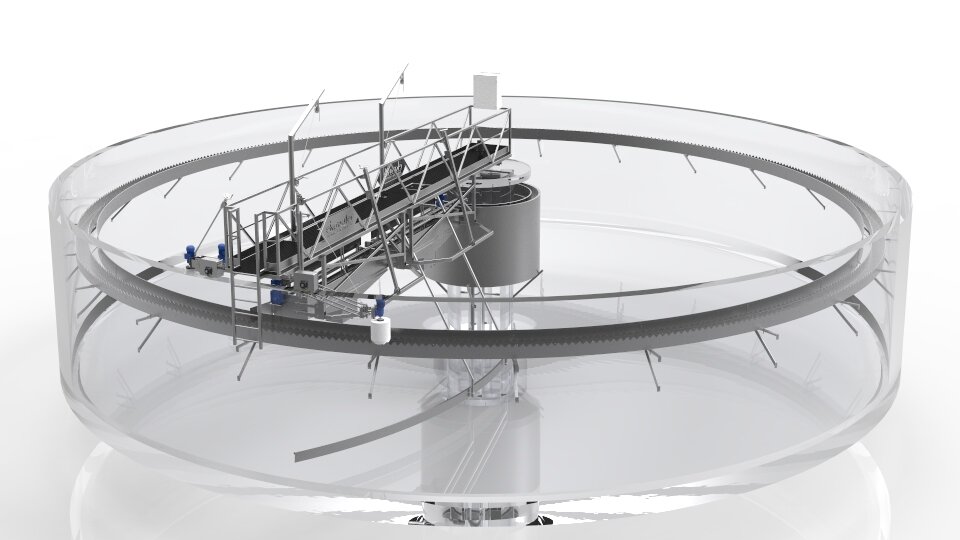

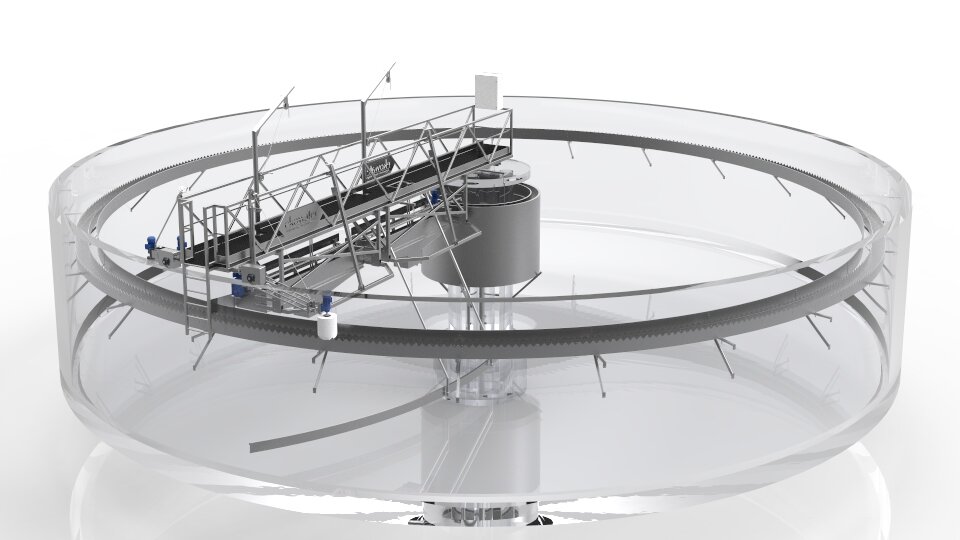

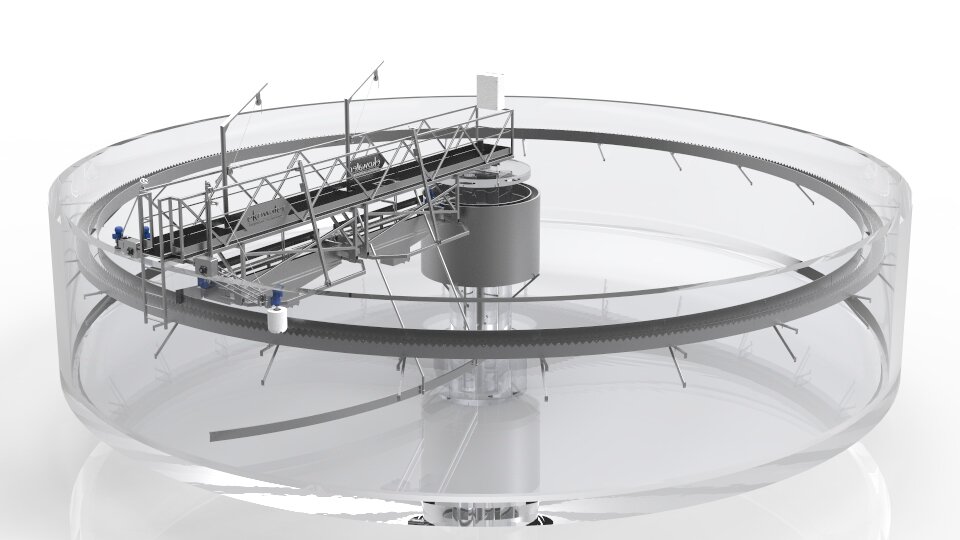

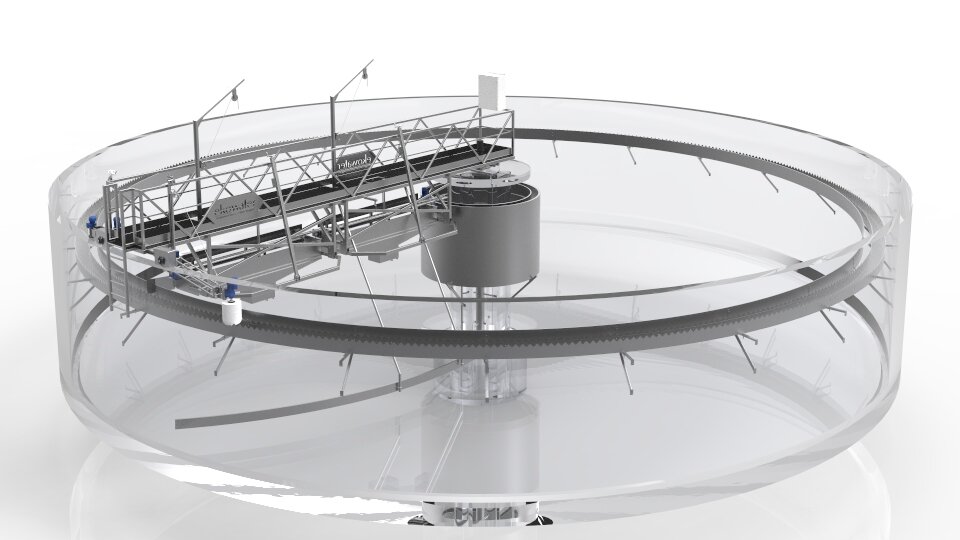

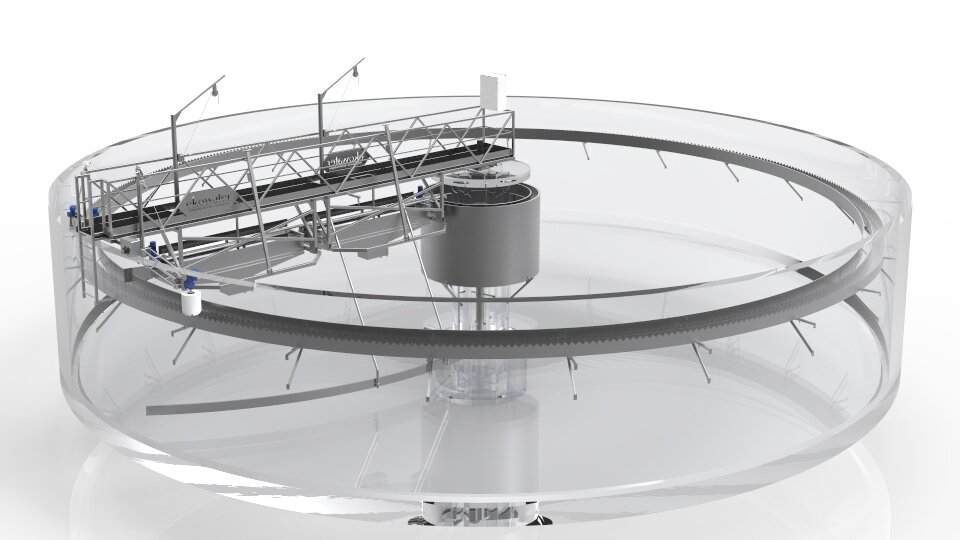

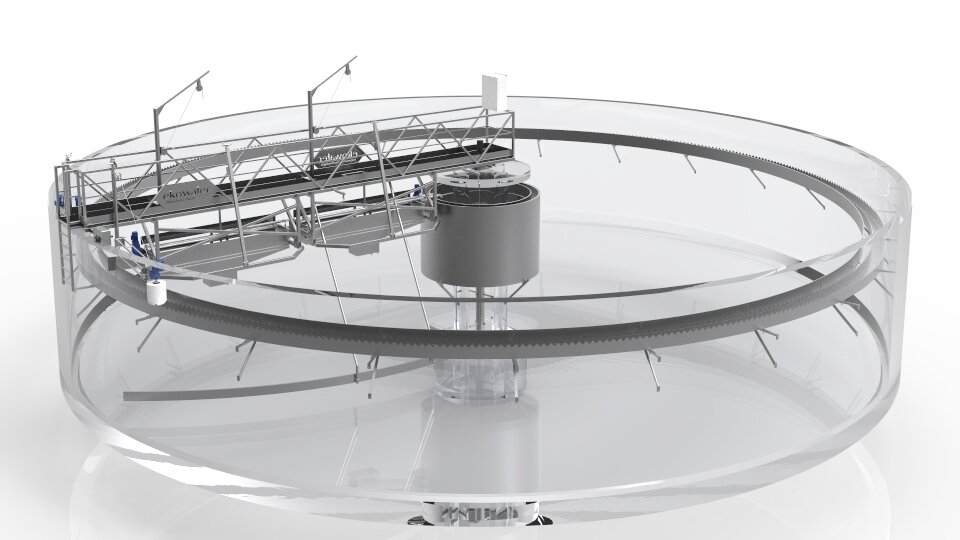

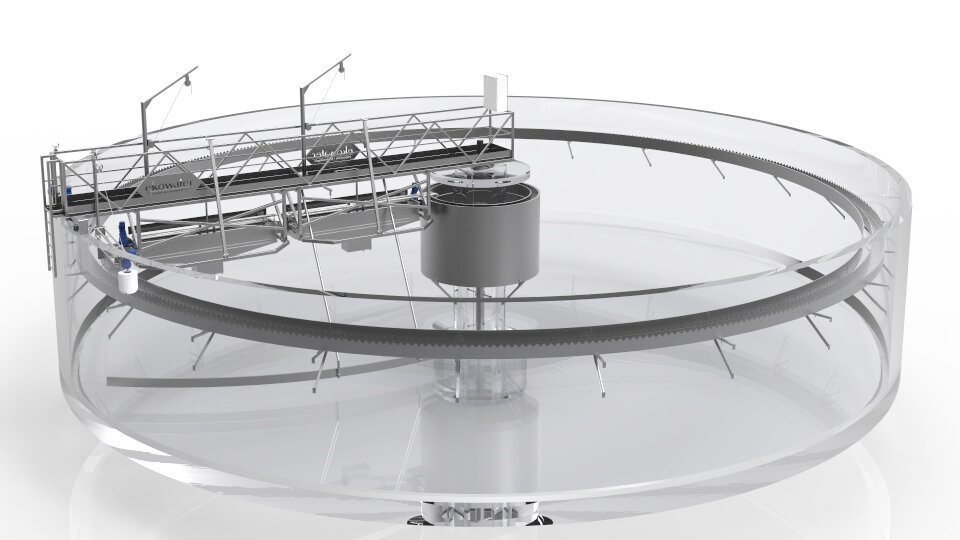

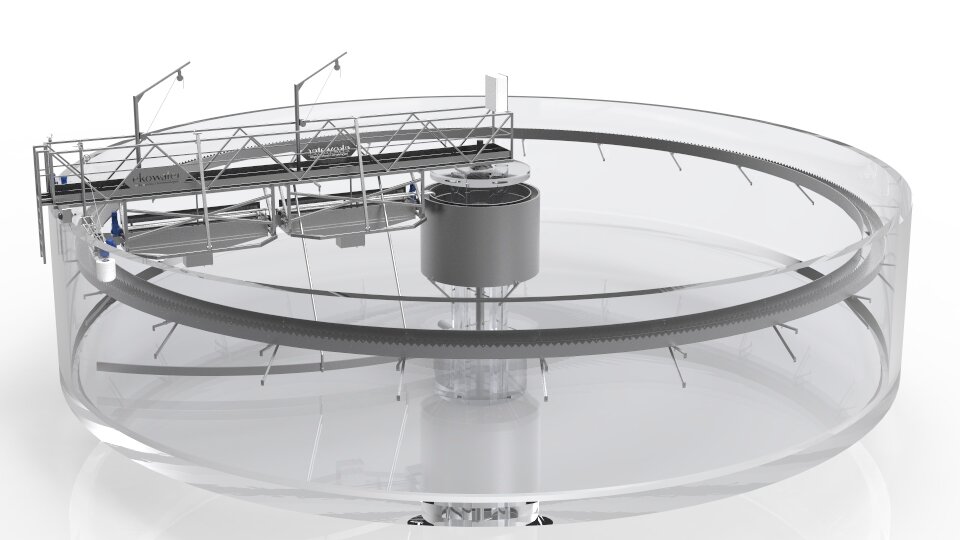

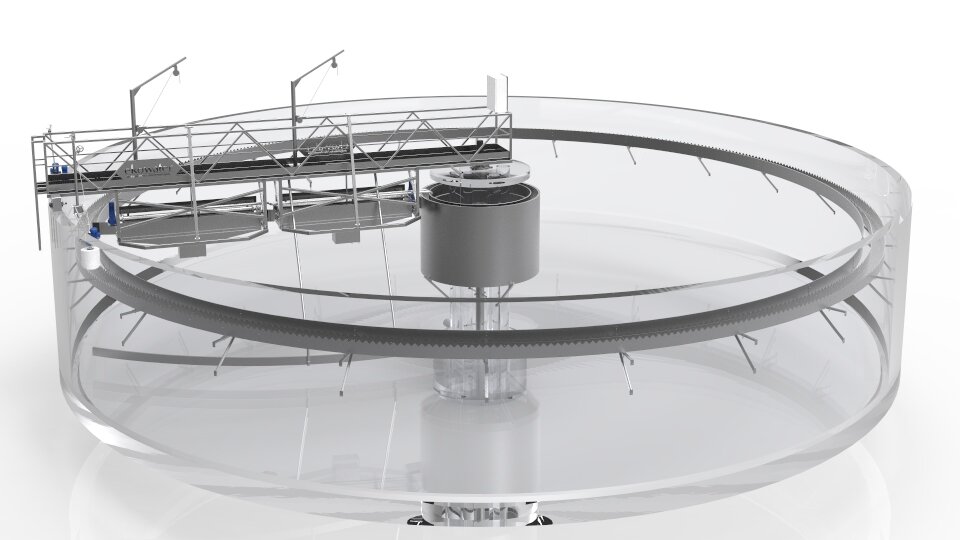

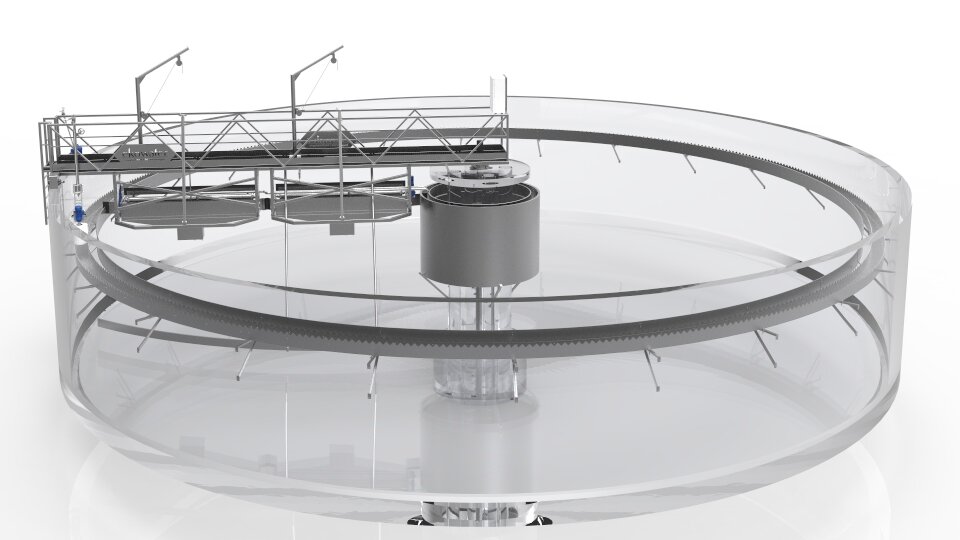

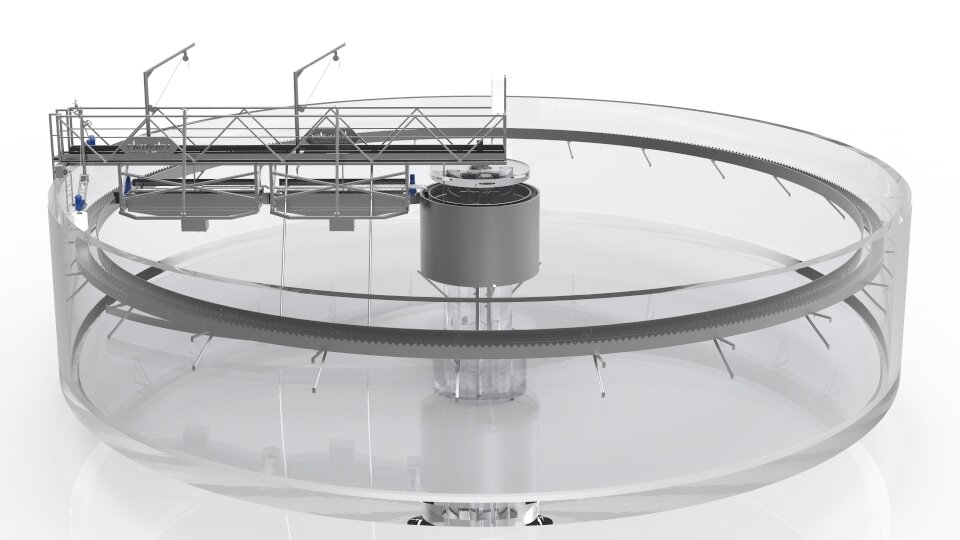

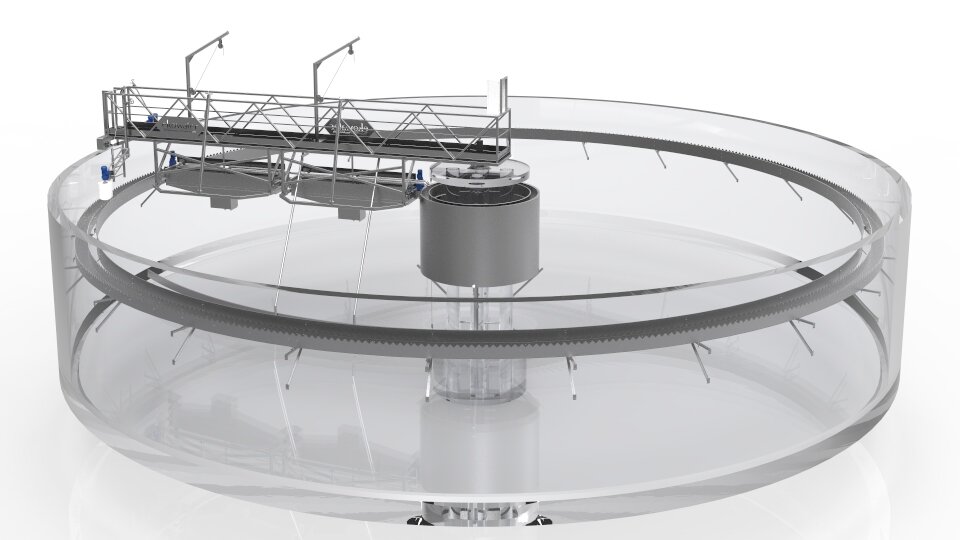

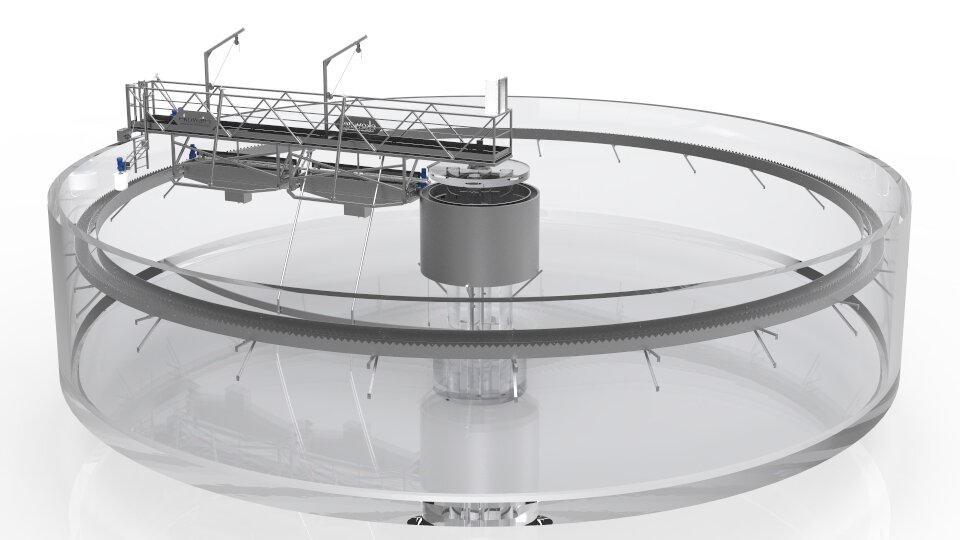

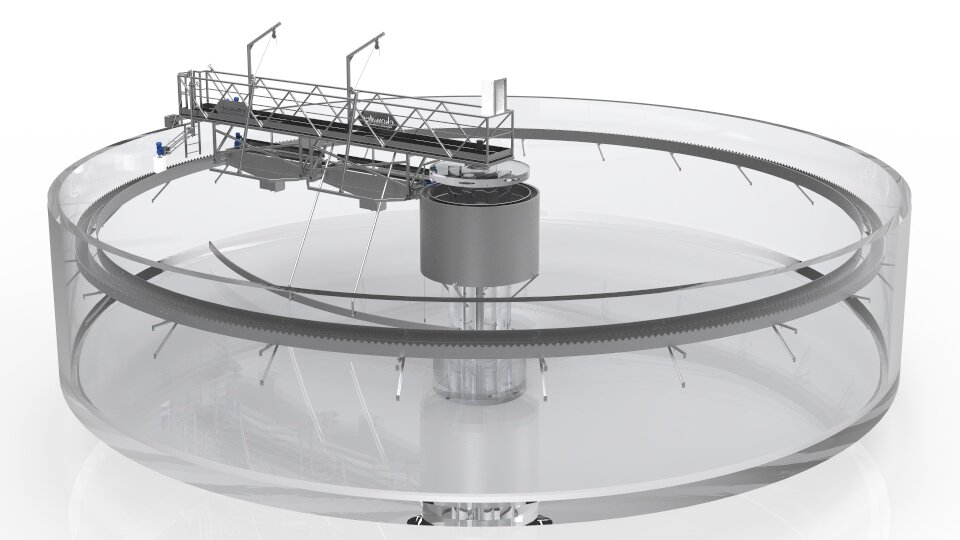

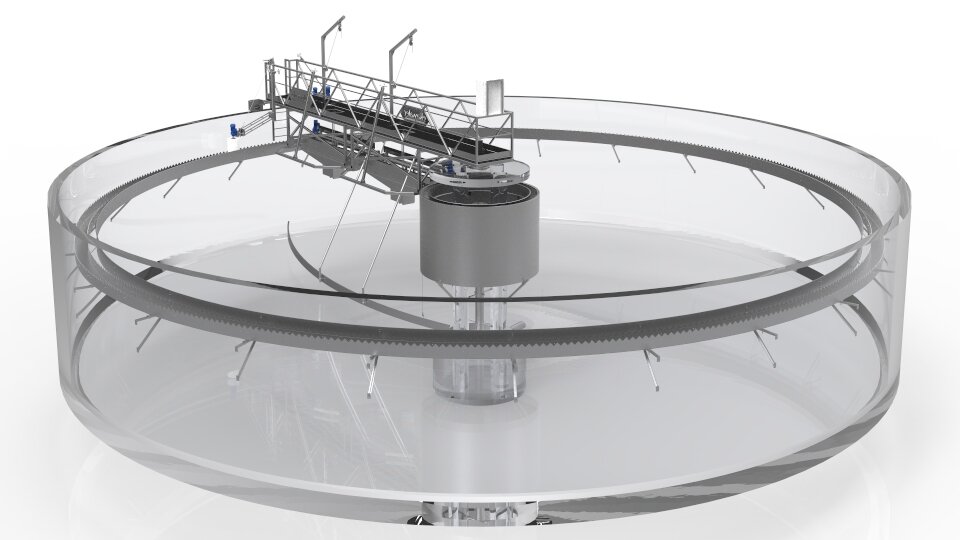

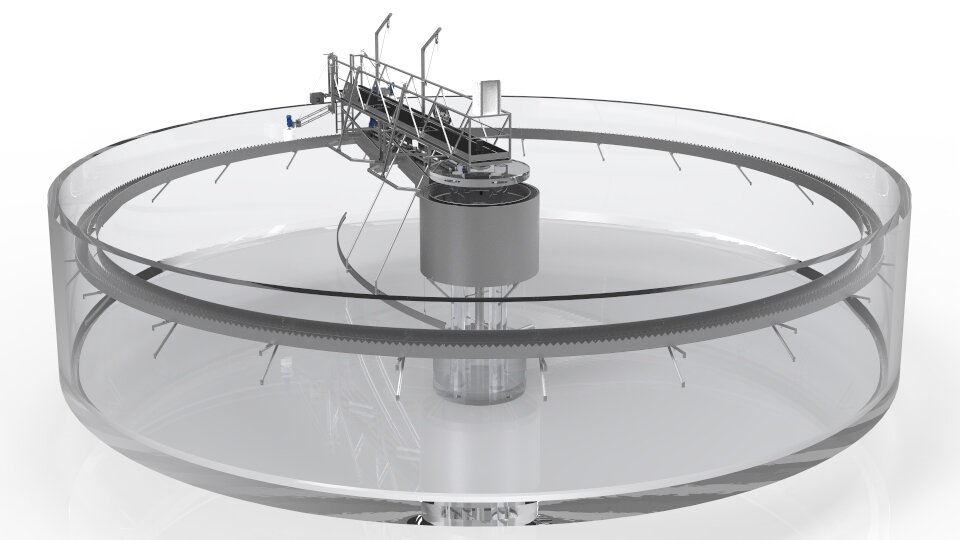

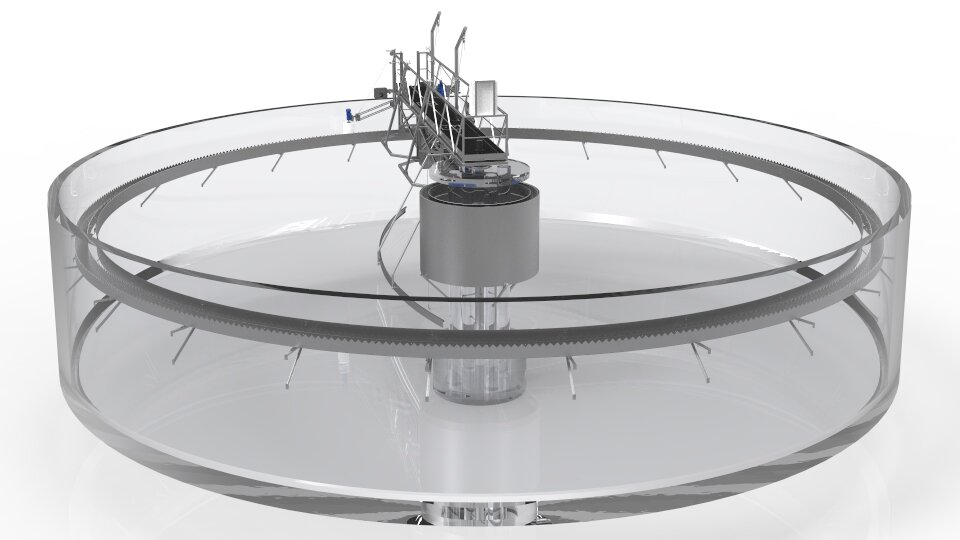

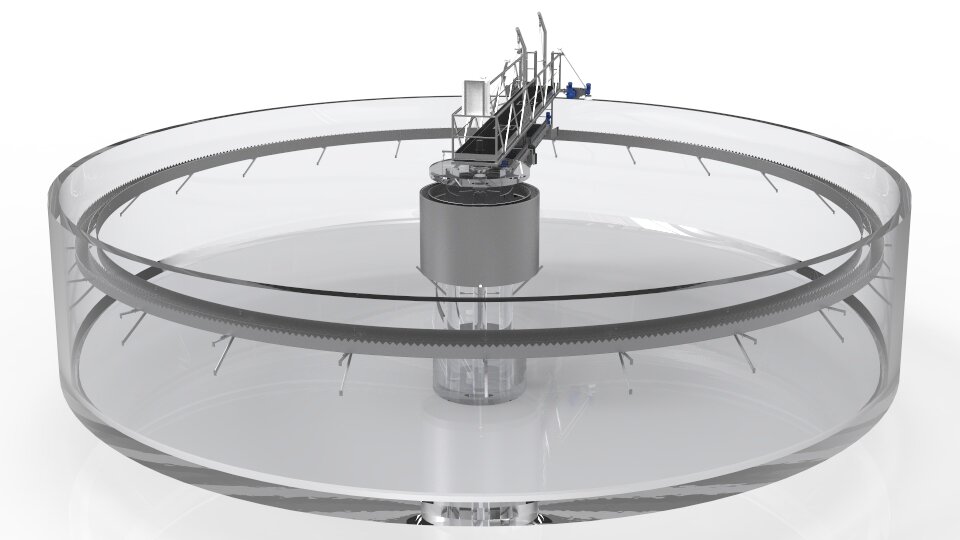

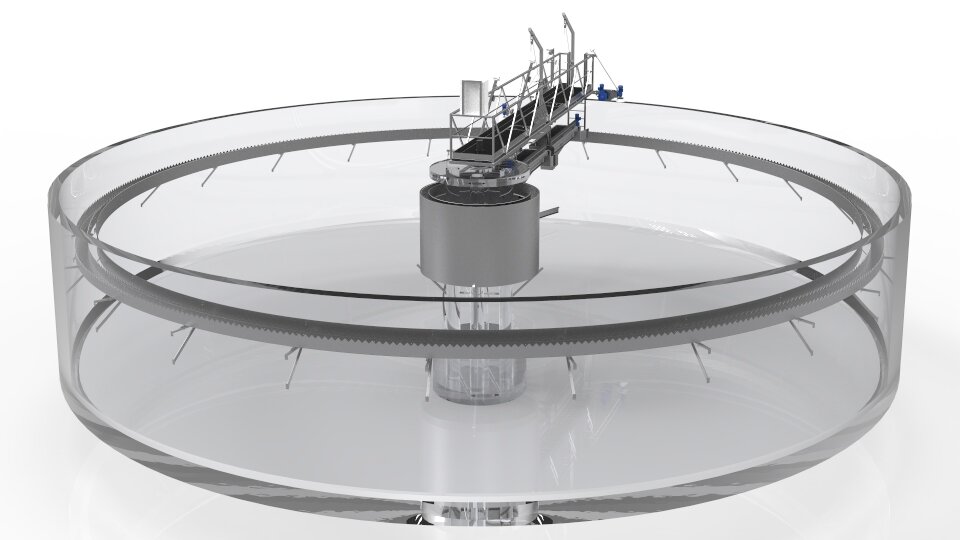

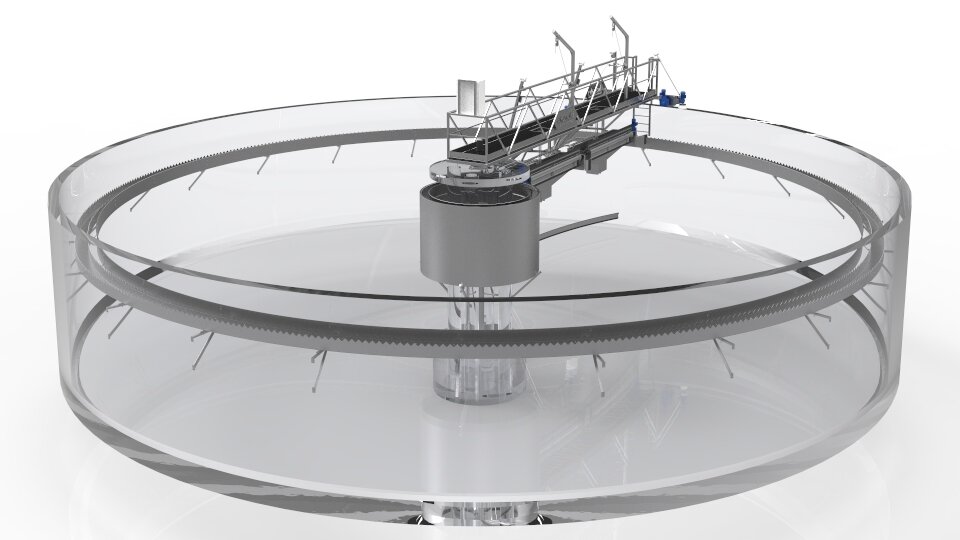

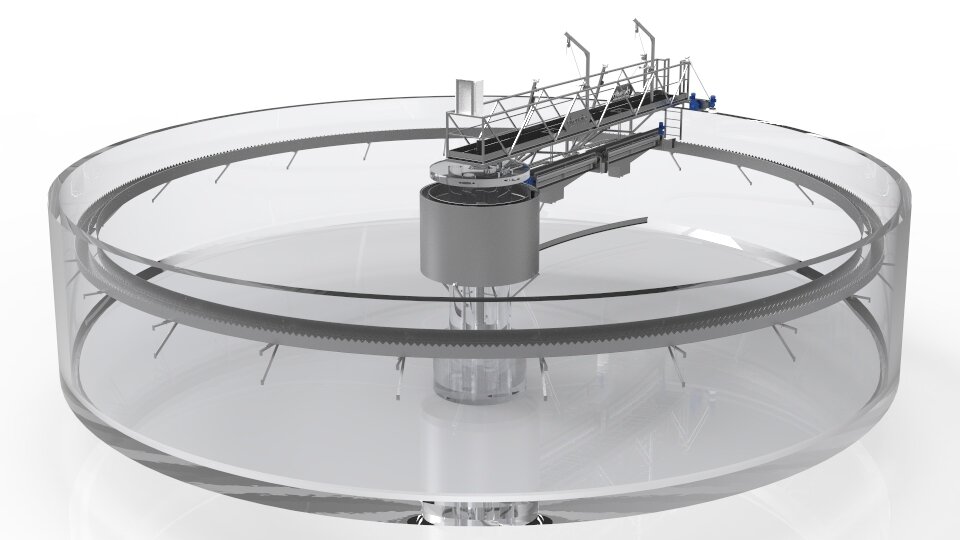

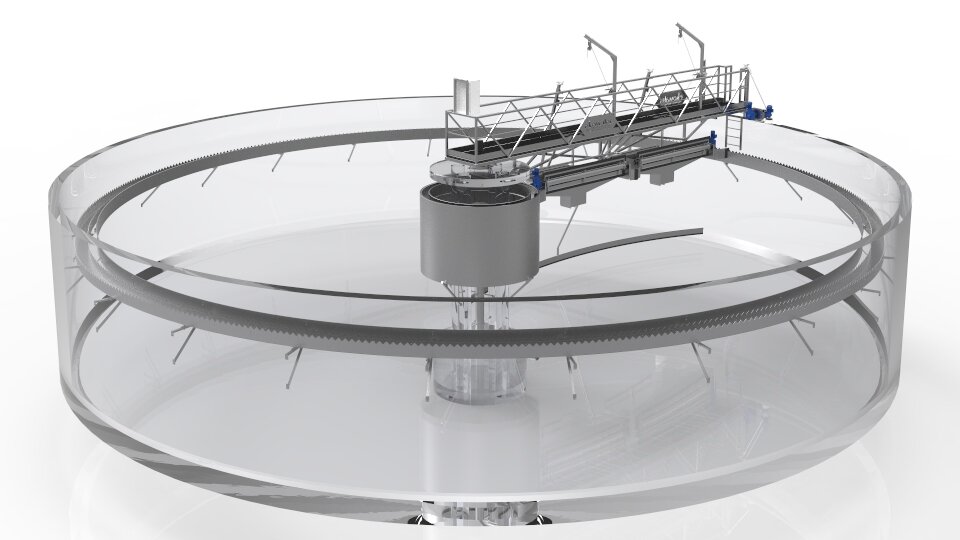

Ekowater’s circular scrubber is used to separate and remove sludge from the bottom of the container as well as sludge floating on the surface in a continuous manner. It can be utilized in municipal and industrial sewage treatment plants.

Activated sludge is separated from the sewage in secondary clarifier. The mixture of sludge and sewage is transported to the central part of the clarifier where diffusion drum is installed. Properly chosen shape of the drum does not impact the sediment accumulated on the bottom of the tank as some fresh sewage flows inside. Sinking sludge is swept on an ongoing basis by the bottom scrubber to the hopper and transferred from the clarifier via a pipeline.

Floating particles are transported to the dumping chamber through innovative scrubber effluent unit. This solution is far more effective than arms of a traditional scrubber. Properly designed rotating scrubber separates the floating sludge from the sewage, to the extent that only flotation froth is moved to a dumping chamber and then pumped out. Immersion of the surface scrubber effluent can be regulated from the bridge without the use of any additional tools.

The outflow occurs through a sawtooth overflow weir which constitute a part of steel channels located by the wall. The deflector, placed by the sawtooth overflow weir, prevents floating matter from entering the outlet.

Certificates

The device is produced by the company certified by: ISO 9001, PN-EN 1090-2 and ISO 3834-2

Material

Duplex stainless steel AISI 304, AISI 316

Circular scrubber effluent: