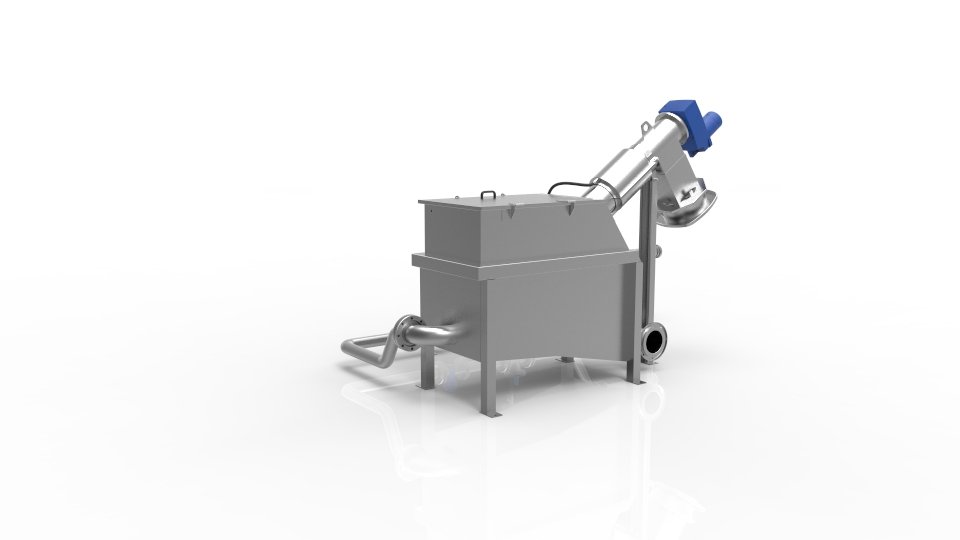

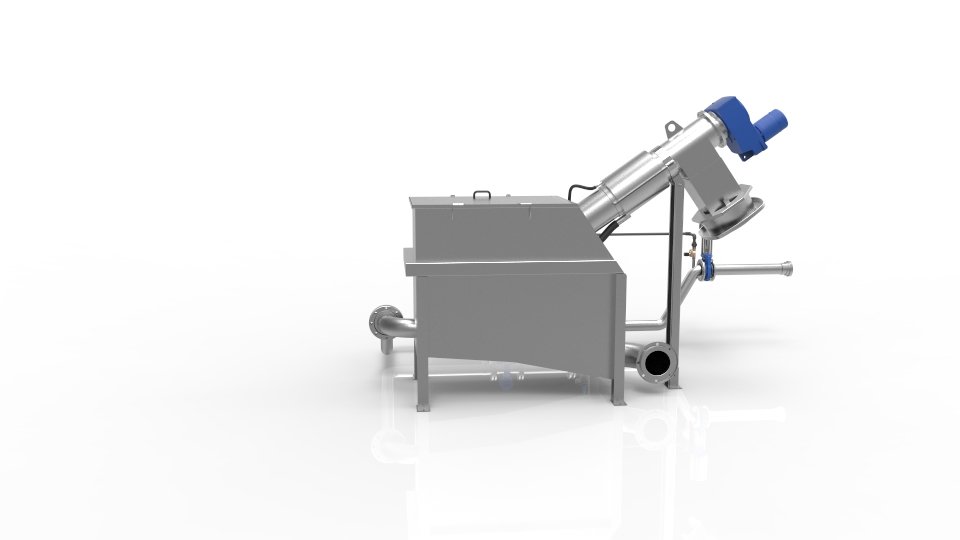

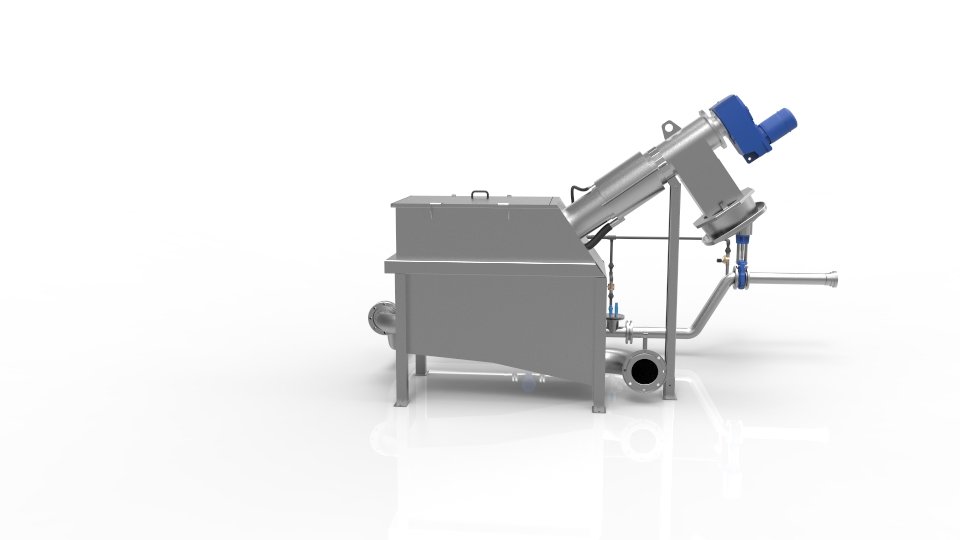

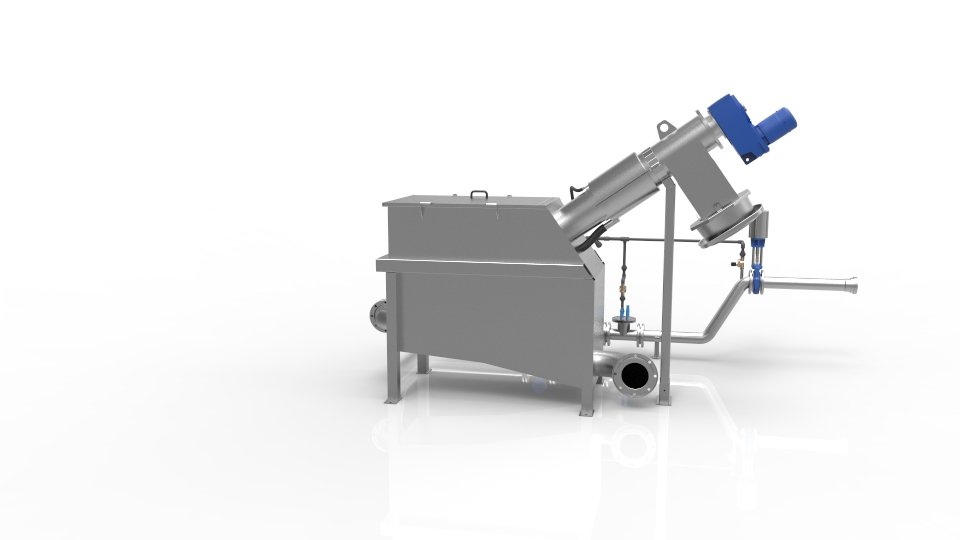

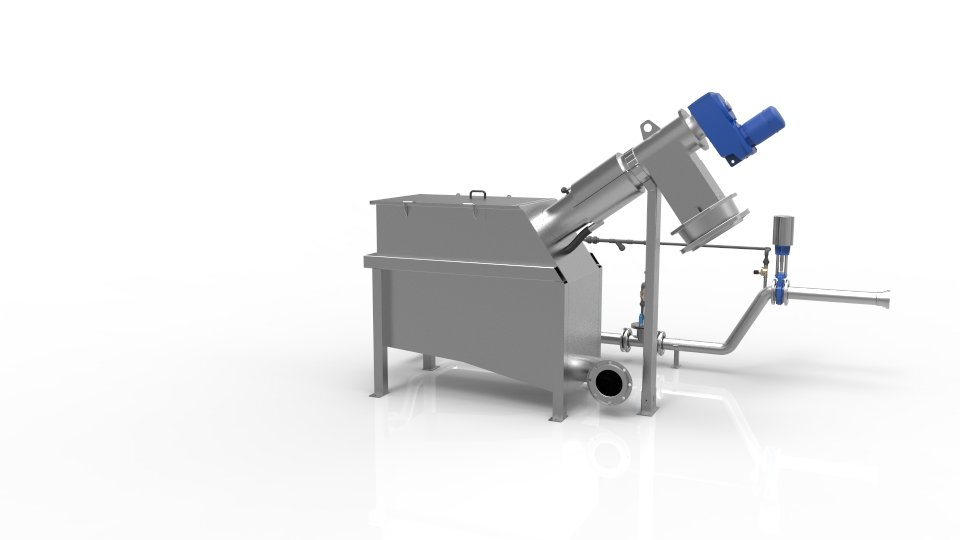

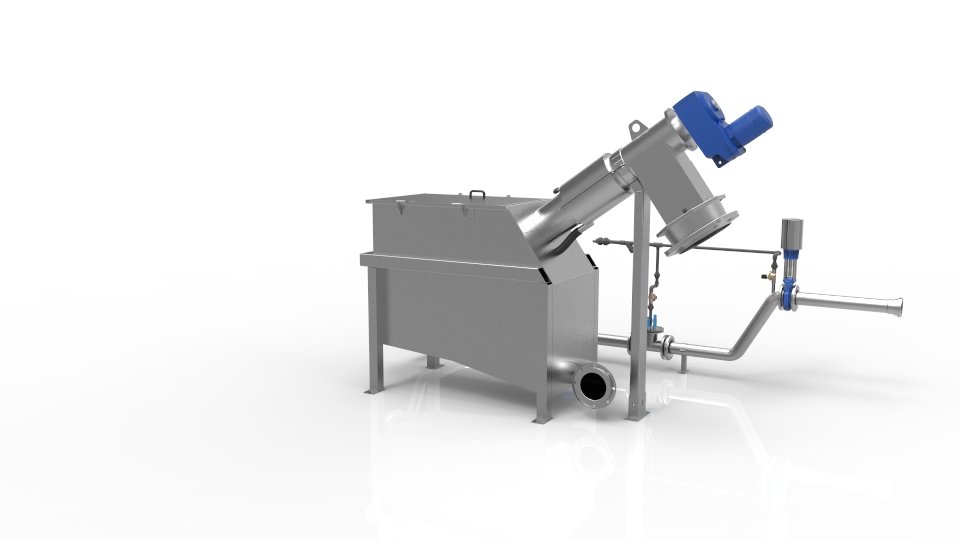

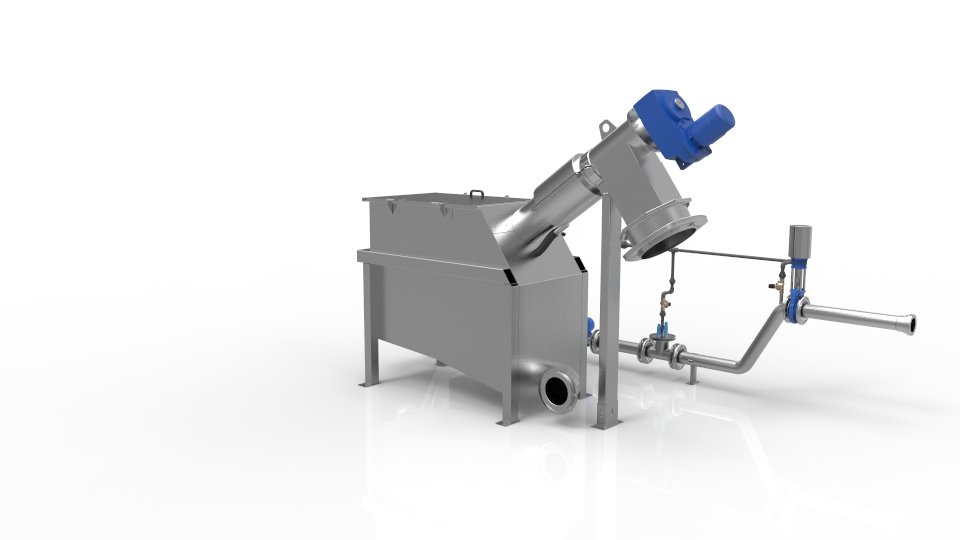

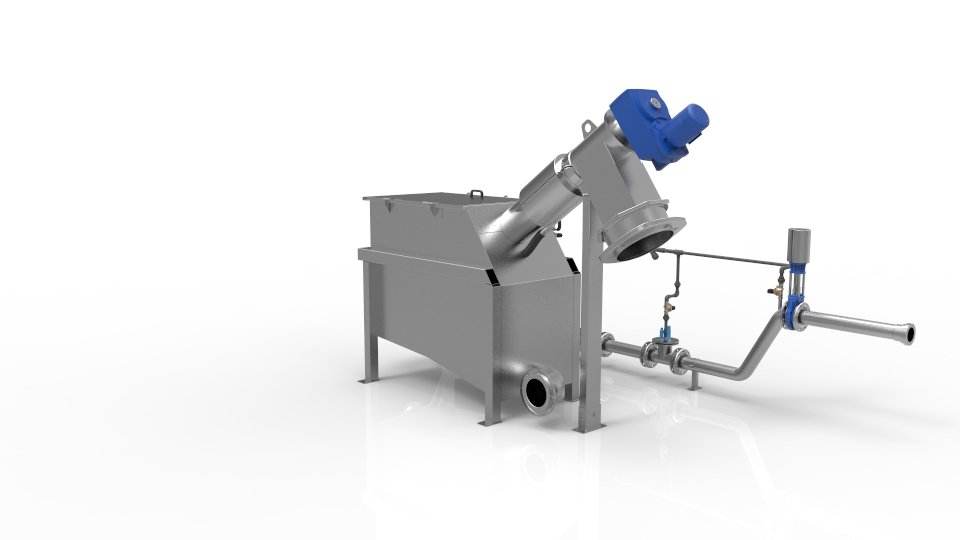

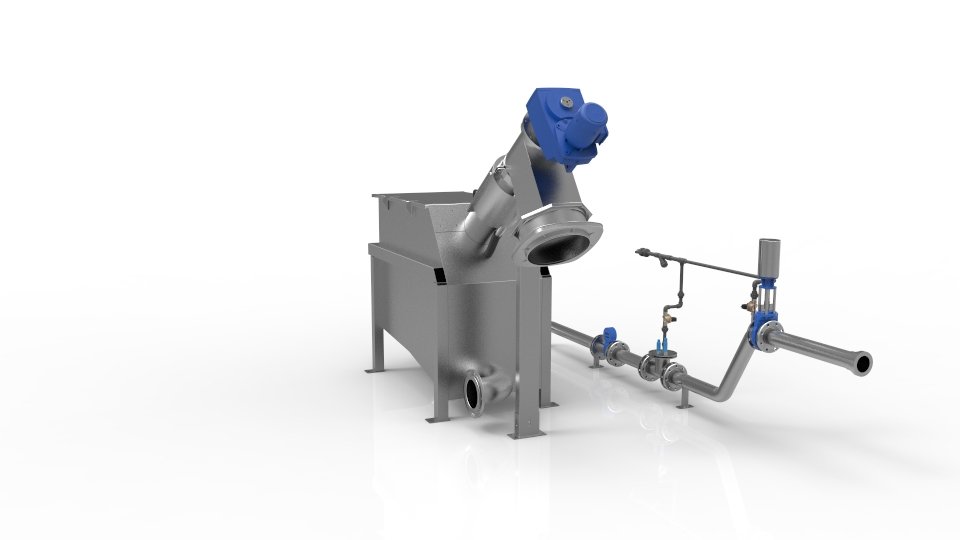

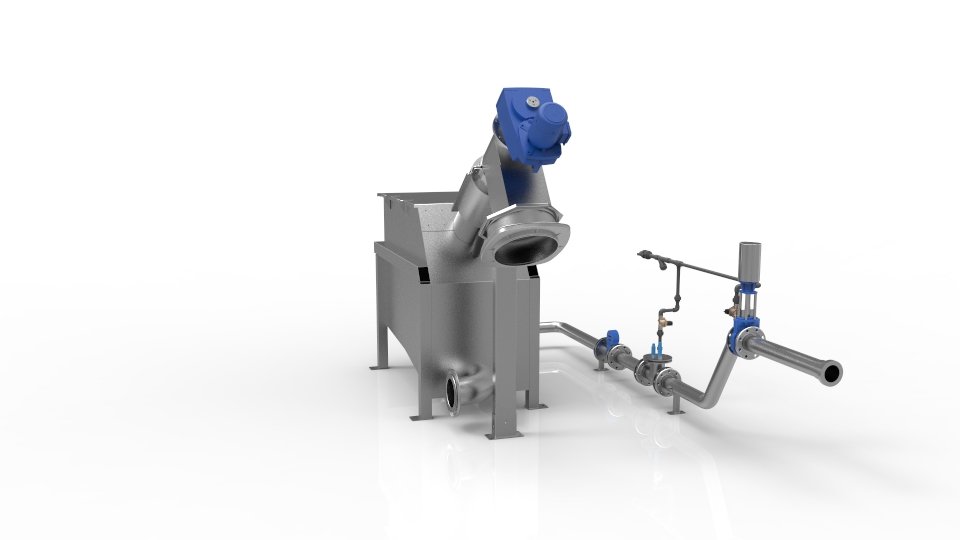

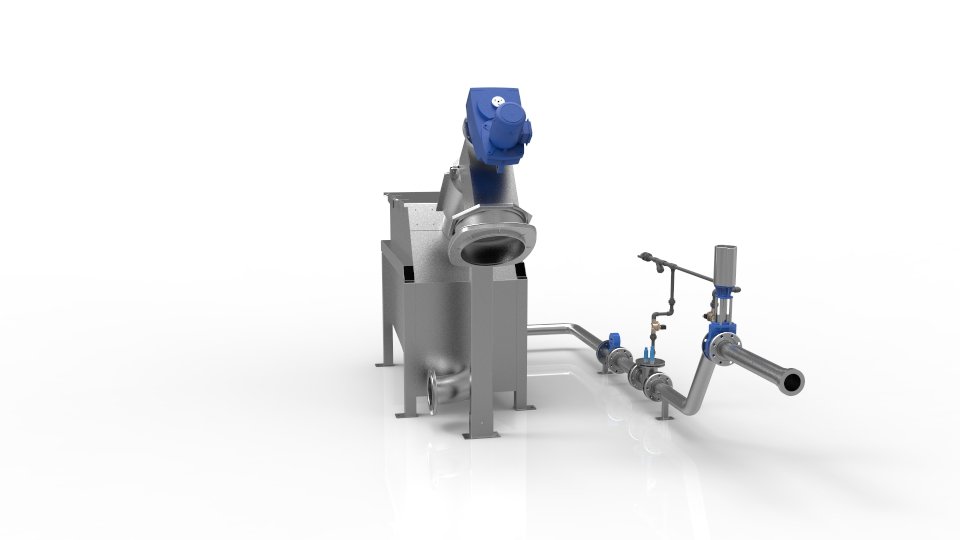

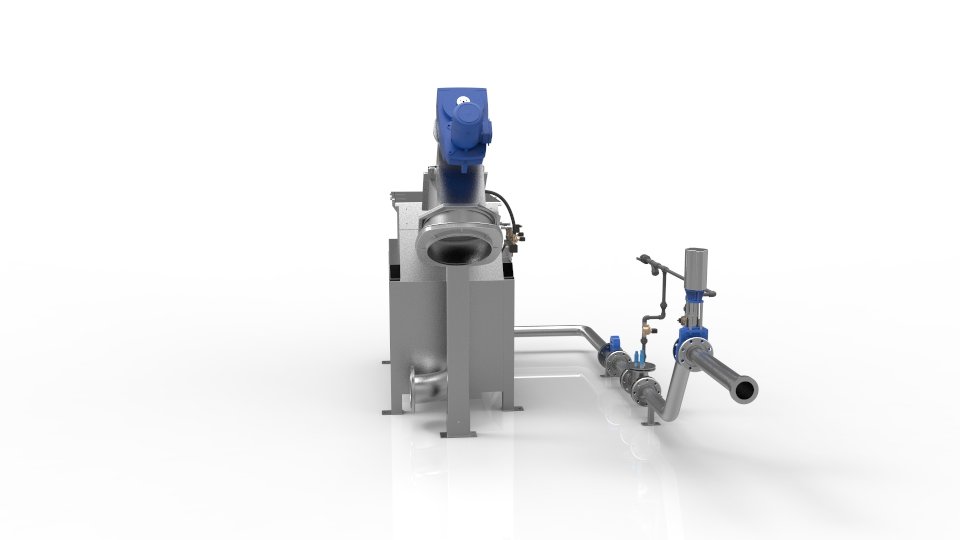

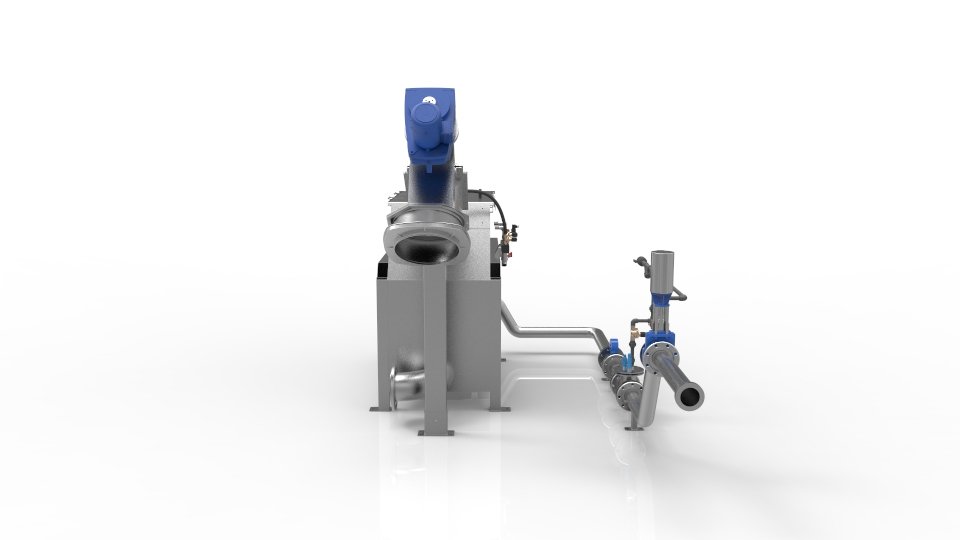

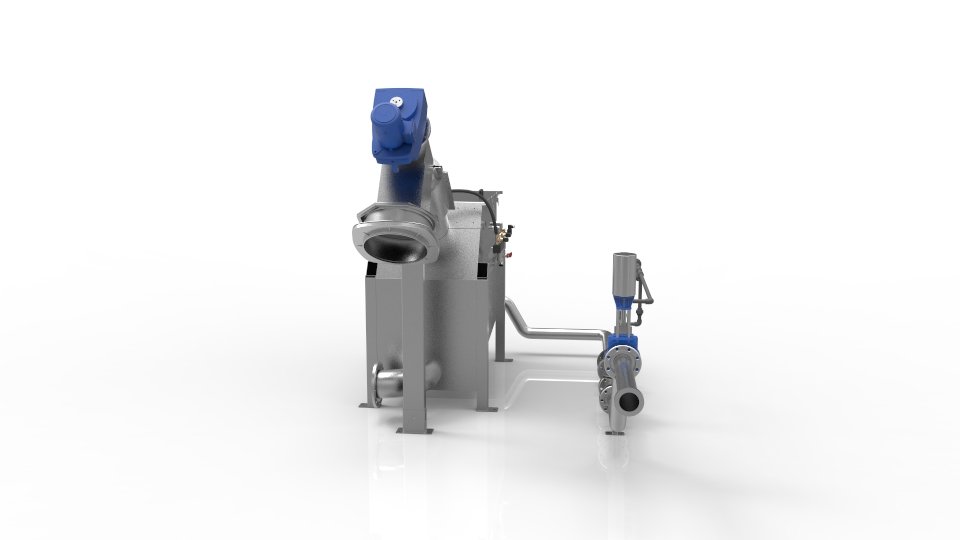

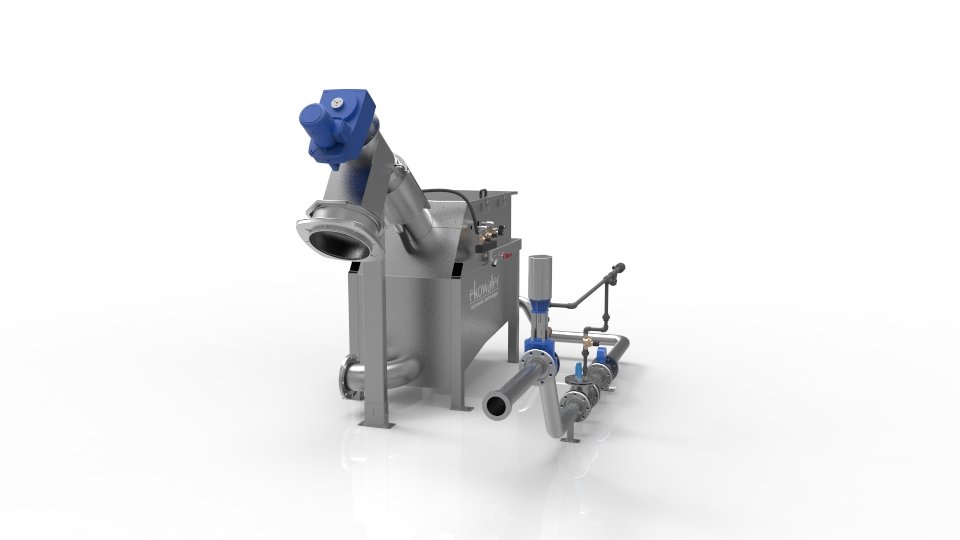

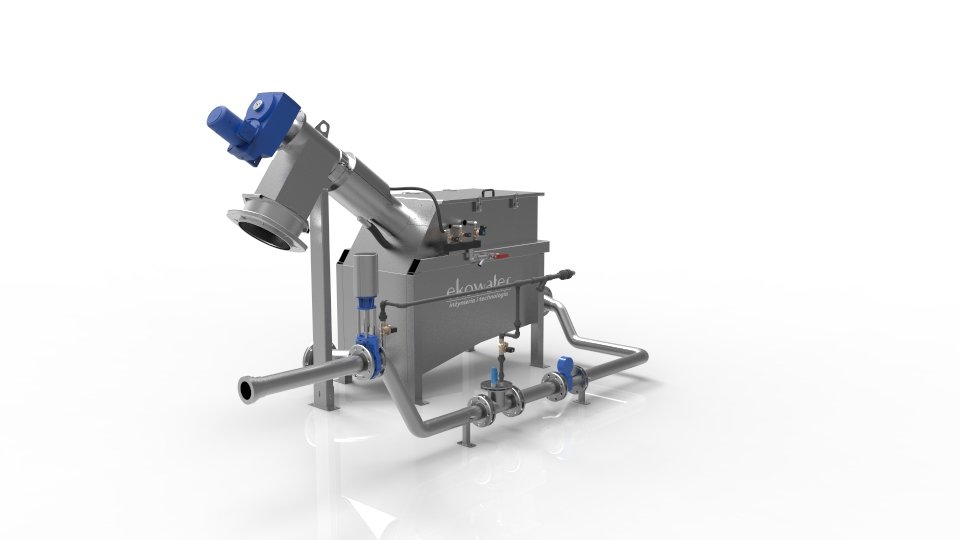

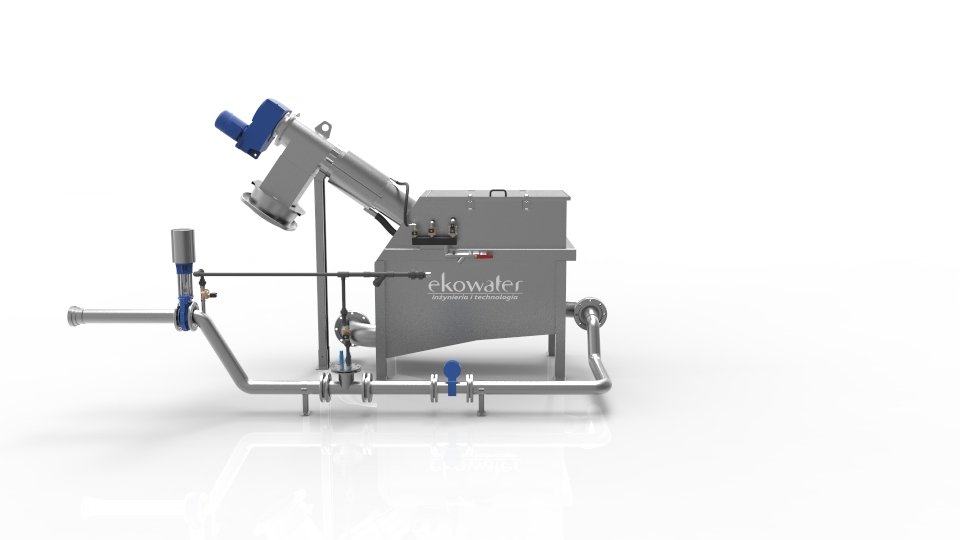

In order to empty the septic tank, the drain hose of a slurry tank is attached to the collection point via Chicago coupling. Once carriers identify themselves by bringing the card to the card-reader, the pneumatic valve opens and sewage is discharged to the device gravitationally. The physical-chemical properties of sewage are automatically measured and if the set out level of parameters is exceeded, the bolt immediately closes blocking the inflow of sewage. Ekowater’s decanting units are optionally equipped with spiral sieve or rotary sieve which mechanically separate and remove contaminants from sewage. Finally, the carrier receives printed confirmation of the amount of discharged sewage. The process is completed when measuring collector and discharge unit are automatically rinsed.